Project update 4 of 7

Funding Goal Reached, Antennas Tuned, and Prototyping Complete!

by Kai GWe’ve got some very exciting news to share: we reached our funding goal and Riotee will come to life! A huge thanks to the backers who have supported our mission to make IoT devices more sustainable. You can look forward to being one of the first users of this exciting new technology.

Lowered Funding Goal

Due to a compressed manufacturing time line, we wanted to get the ball rolling as quickly as possible. In consultation with Crowd Supply, we worked out an arrangement to make that possible. We need about $16,000 to manufacture the first batch of Riotee products. With fees, that came out to $19,000, which was our original funding goal. Now, thanks to a large house order from Crowd Supply, fees account for a smaller portion of our total "amount raised." As a result, $17,000 is now enough for us to hit our manufacturing MoQs.

Antenna Tuning

And this good news has come at the perfect time! We just finalized prototyping the Riotee Module which is now ready for production.

One critical milestone for the last prototype was antenna tuning. The Riotee Module has a custom PCB antenna that is fed from the nRF52833 via two matching networks. One network matches the nRF52833 antenna output to 50 Ohm impedance, the other matches the antenna to 50 Ohm impedance. Layout and PCB stackup are super critical to achieving good radio performance so we closely followed the reference design and comments we received from Nordic Semiconductor as part of a Layout review. As a final step, we sent two Riotee Boards to Norway, where Nordic’s RF experts fine-tuned the components of the matching networks. As part of this fantastic service, we got reports and plots of the radio performance and antenna characteristics after tuning.

Prototyping

Now that we had the component values for the matching networks, we could build two more prototypes of the Riotee Modules to conduct final tests. Below are a few pictures from the lab.

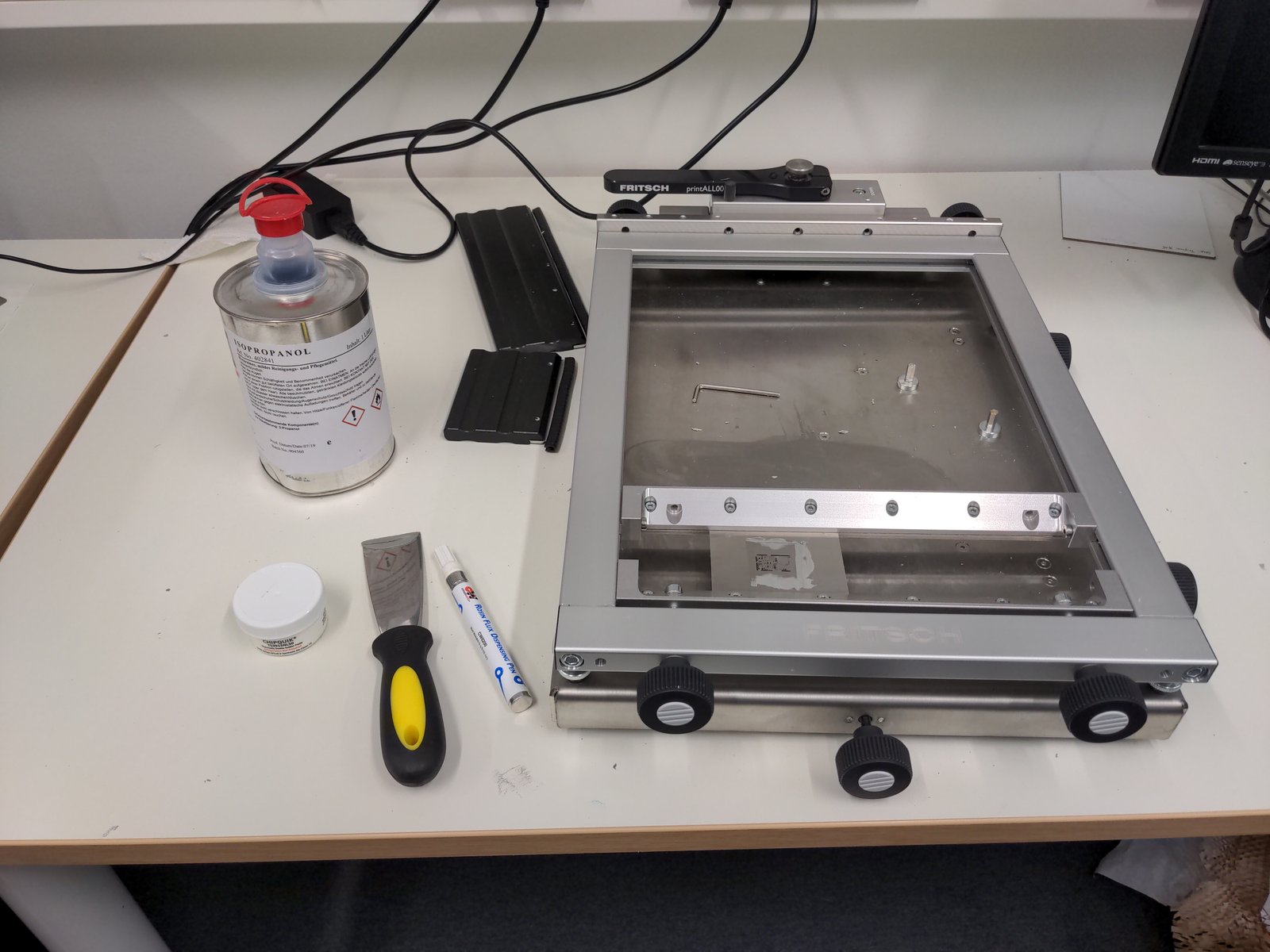

To apply solder paste to the PCBs, we clamp a small, stainless-steel stencil without frame into our stencil printer.

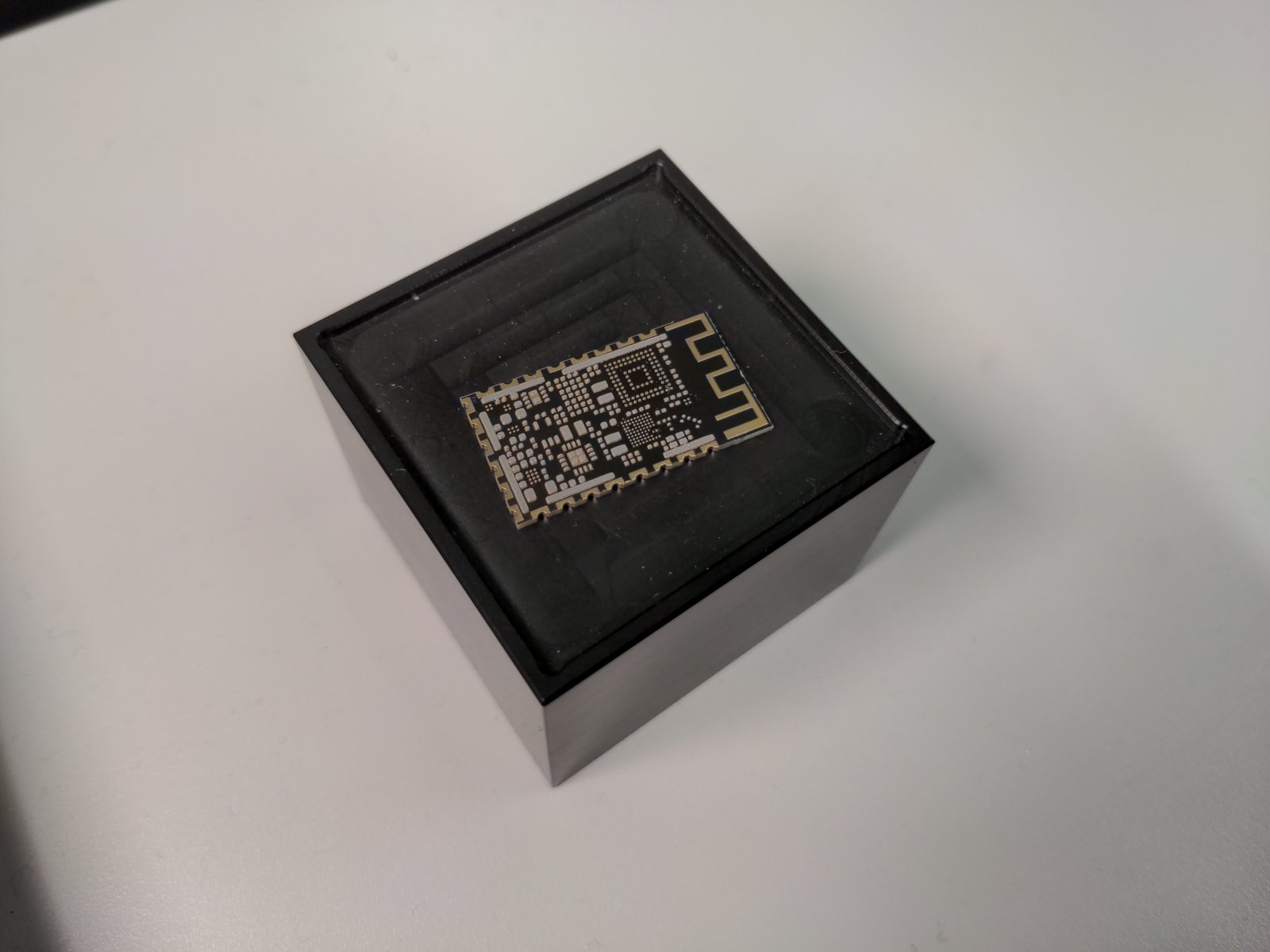

This is a PCB with solder paste printed. You may notice that there’s no paste on some pads. We’ve experienced frequent shorts when soldering the 350 um pitch WLCSP packages with our prototyping process. After some trial and error, we found that it works much better when not applying paste to the WLCSP pads, but instead just wetting them with some flux.

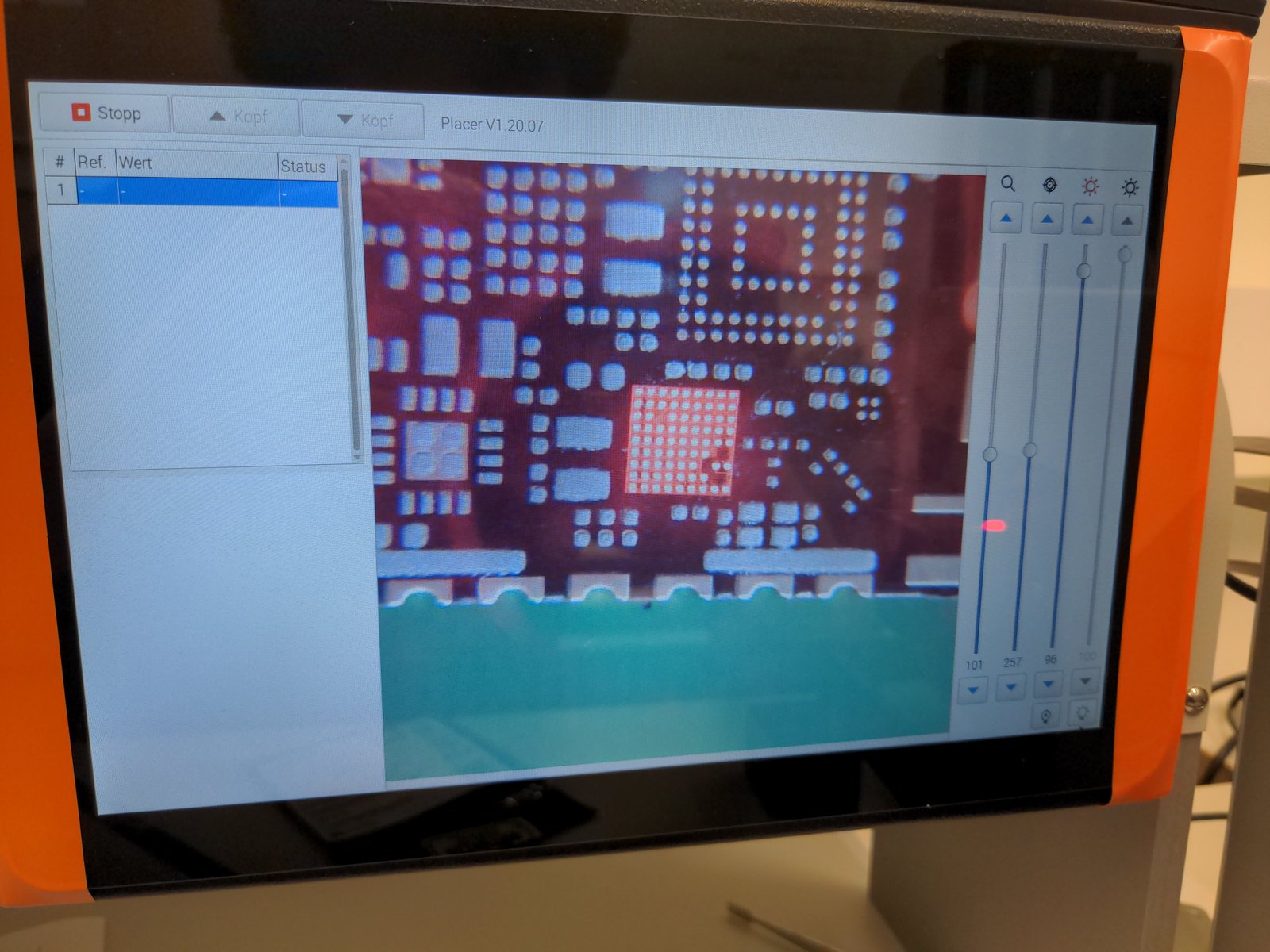

Next, we place the components on the PCB using our manual pick-and-place machine. It has a vacuum nozzle and robust X-Y-Z mechanics for placing standard parts. For fine-pitched BGA, WLCSP, and QFN parts, it offers a special micro-placer unit that sits on the right side of the machine. After picking up an IC and floating it above the PCB, you can pull out a dual camera unit and use it to overlay the image of the bottom of the IC with the top of the PCB on the machine’s display.

Some screws allow moving the table and rotating the IC until the pads on the component and the PCB are perfectly aligned. Finally, the part is placed by lowering the vacuum nozzle. This process is time-consuming and not suited to series production but it achieves great placement accuracy.

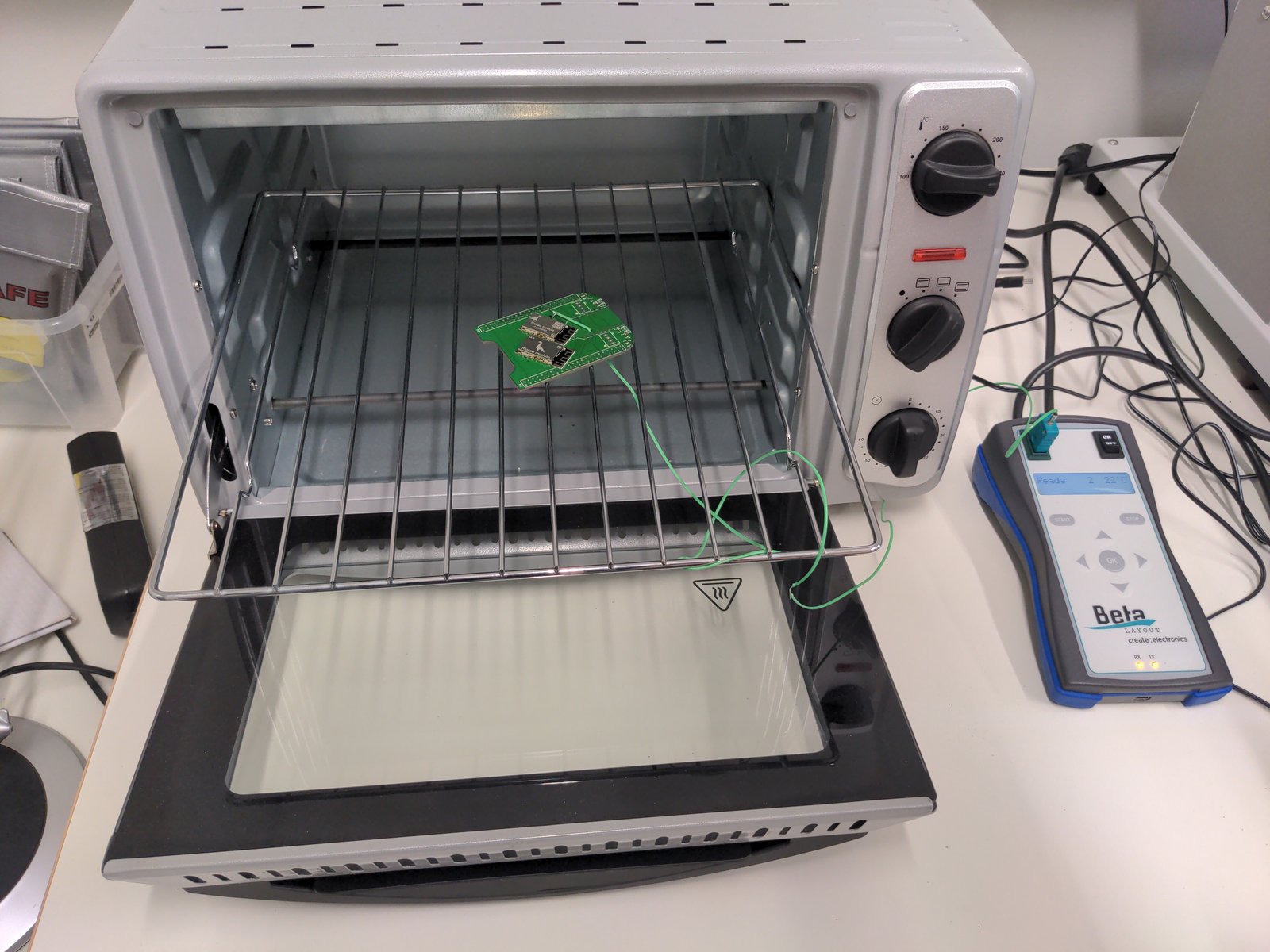

After placing all components, we shove the PCBs into a pizza oven that follows a custom reflow profile programmed into the device on the right side of the image above. After around ten minutes, the PCBs are well done and ready for testing.

Come Check it Out!

All tests passed, and we’ve now got the production data ready to send to our manufacturing partners on the day the campaign ends. We currently see no availability issues with any of our components, so we expect to get the first batch of products ready within few weeks. If you want your Riotee boards to be part of this first batch, consider backing the campaign now!