Thank you for all the support throughout the first week of the campaign. We are very close to reaching our funding goal! And that means it’s time to get excited and start scrutinizing the next big question: how to make USB-Cereal at a scale and ensure quality in every detail.

Timeline & Manufacturing Plan

| Week -5 | Week -4 | Week -3 | Week -2 | Week -1 | C | 2-Week Buffer | Week 1 | Week 2 | Week 3 | Week 4 | Week 5 | Week 6 | Week 7 | Week 8 | 2-Week Buffer | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| QA process & tooling development | 1 | 1 | 1 | 1 | a | |||||||||||

| Regulatory compliance testing | 1 | 1 | 1 | 1 | m | |||||||||||

| Component purchasing | p | 1 | ||||||||||||||

| Shipping components to factory | a | 1 | 1 | |||||||||||||

| PCB manufacturing | i | 1 | 1 | 1 | ||||||||||||

| PCBA assembly | g | 1 | 1 | ship | ||||||||||||

| PCBA testing | n | 1 | ||||||||||||||

| Enclosure manufacturing | 1 | ship | ||||||||||||||

| PCBA/enclosure assembly | e | 1 | ||||||||||||||

| Label design & manufacturing | n | 1 | 1 | ship | ||||||||||||

| Packaging and shipping to CS | d | ship |

The table above gives a high level overview of what needs to happen in the final weeks of the campaign and after its completion. It contains sufficient buffer that we are confident we can deliver USB-Cereal in time if not ahead of our projected July shipping estimate!

USB-Cereal Manufacturing, Testing, and Engineering Verification

Testing

All units will undergo several stages of testing to ensure that our PCBs and solder joints are free from manufacturing defects and to verify that every component is populated correctly.

- Every PCB undergoes visual inspection prior to component population.

- After the reflow cycle, PCBAs are subjected to visual inspection once again.

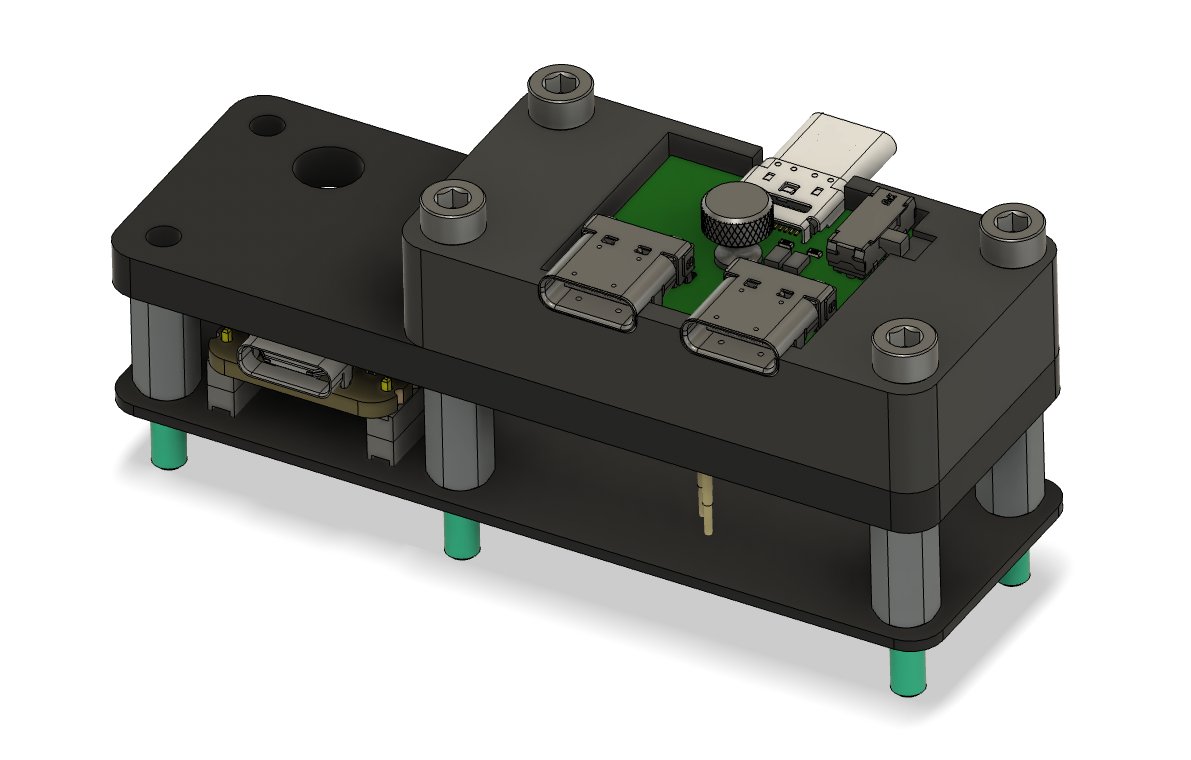

- The PCB assembly now goes into the bed-of-nails test jig that checks UART communication, LED operation, and correctness of the voltage reference levels.

- USB-Cereal is attached to the PC to program the USB-to-Serial bridge, which works in tandem with the test-jig controller to test the correctness of the last remaining connector.

- USB-Cereal pass-through ports are are connected to the USB-C cable tester to ensure that each connector contains no soldering or internal defects.

The entire test procedure should not take more than a minute per board!

Engineering Verification

Well ahead of manufacturing, we have ensured that that USB-Cereal works for most use cases. We will re-qualify the device for any copper changes made to the PCB. In addition, we have carried out:

- A UART loopback test at maximum baud rate up to 3,000,000 baud. It's very uncommon to see UART data rates go that high, yet we are delivering the maximum communication speed the USB-to-Serial converter IC is capable of. (Note that the actual baud rate is physically affected by other factors as well, so a mindful end-system design is still necessary.)

- Stress-testing the USB-Cereal's VBUS routing and connector resistances by charging the laptop at 90 W per the USB PD specification.

- A USB Type-C pass through routing is verified using a read-write speed test with a high-speed USB Type-C flash drive. We have also verified Thunderbolt operation through the port using a laptop-to-dock connection with a monitor attached to the dock.

- Testing of the mechanical robustness of the enclosure to drops, cable pulling, and reasonable mishandling.

Thank you all once again for your support, comments, and questions!