Project update 1 of 10

Design Improvements, Accessories, and Testing Plans

by vileer dHi everyone, it has been awhile since we pre-launched the Pi-Cast project. Over the past few months, our main focus has been on redesigning the form factor of the Pi-Cast, optimizing the circuit, and developing new accessories.

For now, the Pi-Cast PCB design is almost finalized. Regarding accessories, we have developed three kinds:

- Pi-Cast Hat: with plenty of the interfaces a PiKVM device should have.

- Pi-Cast KVM Switch: a two-port KVM switch that switches not only the HDMI and USB signals but also the ATX signals.

- PCIe-to-USB-3.0 Baseboard: provides three USB 3.0 ports and one M.2 B Key interface for an LTE/5G roaming card.

You can use the PCIe-to-USB-3.0 Baseboard with the other two accessories to greatly expand the Pi-Cast’s capabilities. All of this work has been documented on our new pre-launch page, where you can find more detailed information.

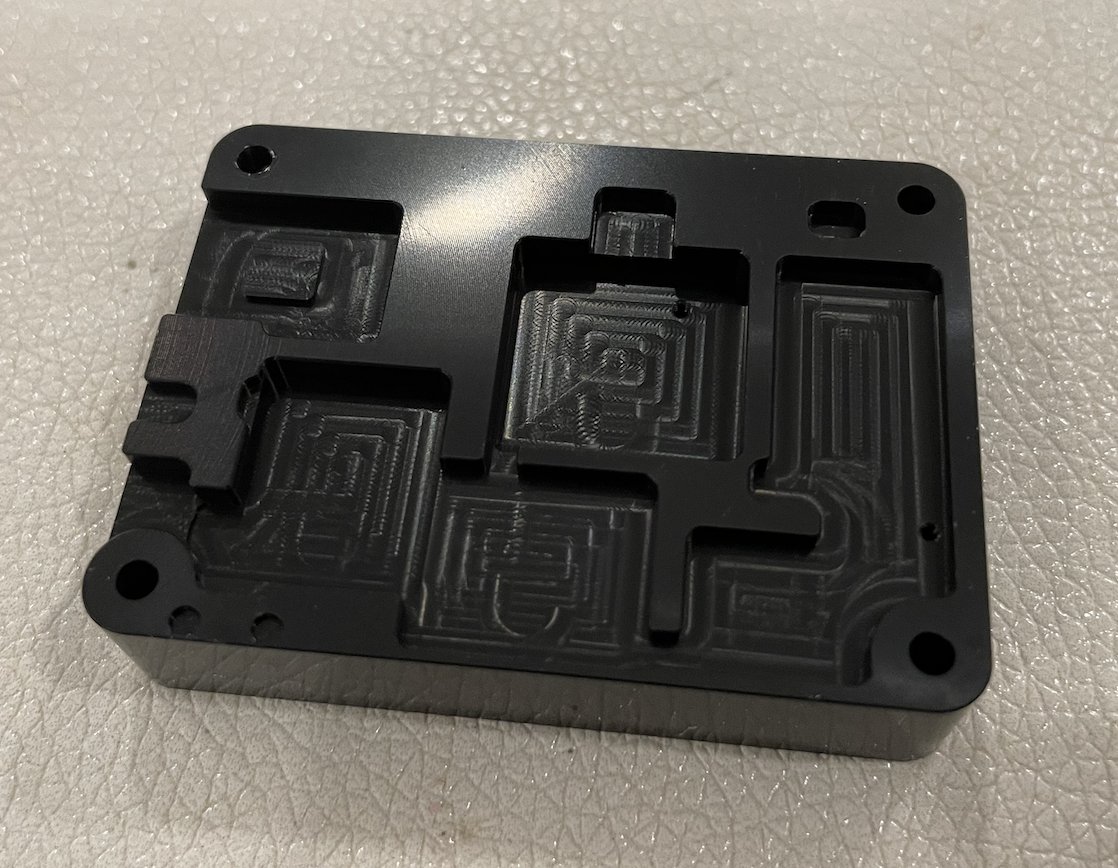

Now let’s talk about work we haven’t posted on the pre-launch page. We know that a bare PCB is not suitable for everyday use. Therefore, we have designed a metal enclosure to protect the Pi-Cast. You can see an early prototype of the enclosure below:

We also plan to design more enclosures to cover the Pi-Cast when it has accessories attached.

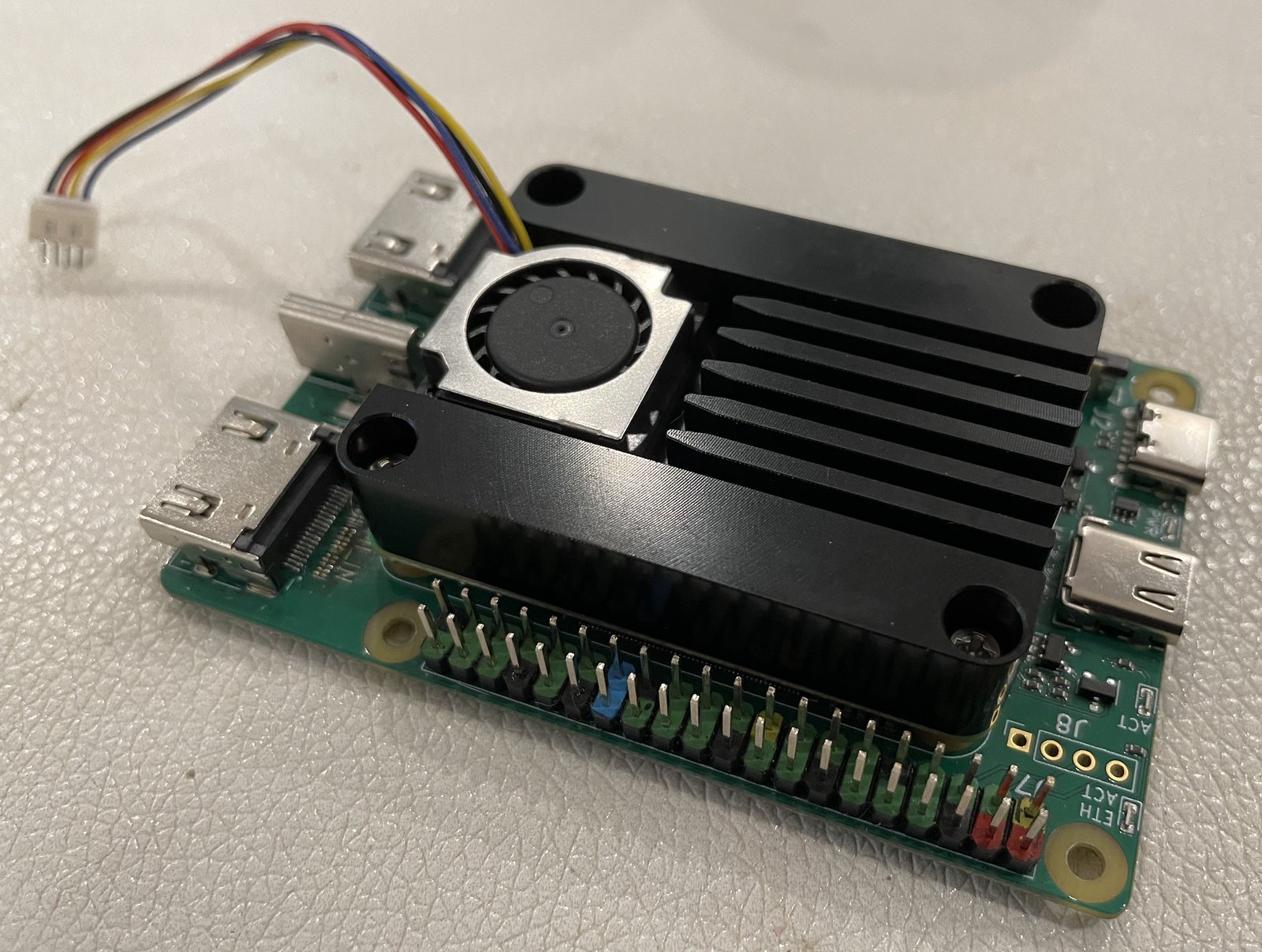

Furthermore, we understand that the CM4 can become very hot when running at full load. This can lead to performance issues due to throttling. So we custom-designed an aluminum heat sink using CNC technology. The heat sink is in direct contact with the areas on the CM4 PCB that do not have components, and the CPU, RAM, EMMC, Ethernet PHY, PMIC, and wireless module are connected to the heat sink using a 1mm-thick thermal silicone pad. We also added a PWM-controlled cooling fan, shown below:

In addition, the top of the heat sink can be connected to the enclosure with a 1 mm-thick thermal silicone pad, which increases the effective area for heat dissipation.

Lastly, let’s talk about our small-batch production plan. Since Pi-Cast PCB design work is almost complete, we’ll be producing a small number of samples in the next few weeks for early testing and media outreach. Speaking of media outreach, if we have any extra samples left, we would be happy to provide them to YouTubers with subscribers interested in Pi-Cast for product reviews. If you are interested in reviewing our product, please contact us at vileer.com@gmail.com so we can add you to the list.

That’s all for this update. Until next time!