Project update 5 of 11

[Video] Pixel Panels Stack - Skip The Evil Popcorn! + DIY LED Cube

by Benjamin HThis is the last week of the campaign! Only 7 days to go! It’s not too late to get your order in, or add an 8x8 LED Matrix!

In this update: All about our 8x8 LED panels, how quality gets baked-in during manufacturing!

While the main focus of the campaign is the Pixelblaze V3, the 8x8 LED panels are a part of it and are a great way to experiment with 2D or even 3D animations!

2D and 3D Pixels!

The 8x8 LED Matrix can be stacked to create larger arrays, or assembled into a cube or other shape!

Check out these awesome pattern demo videos that Jeff created as part of the new pattern documentation that ships with V3! Some have 1D, 2D and 3D together all synced up with Firestorm!

Xorcery 2D/3D

Fast Pulse

Matrix 2D Honeycomb

Pulse 2D

Spectrum analyzer

Spiral twirls 2D

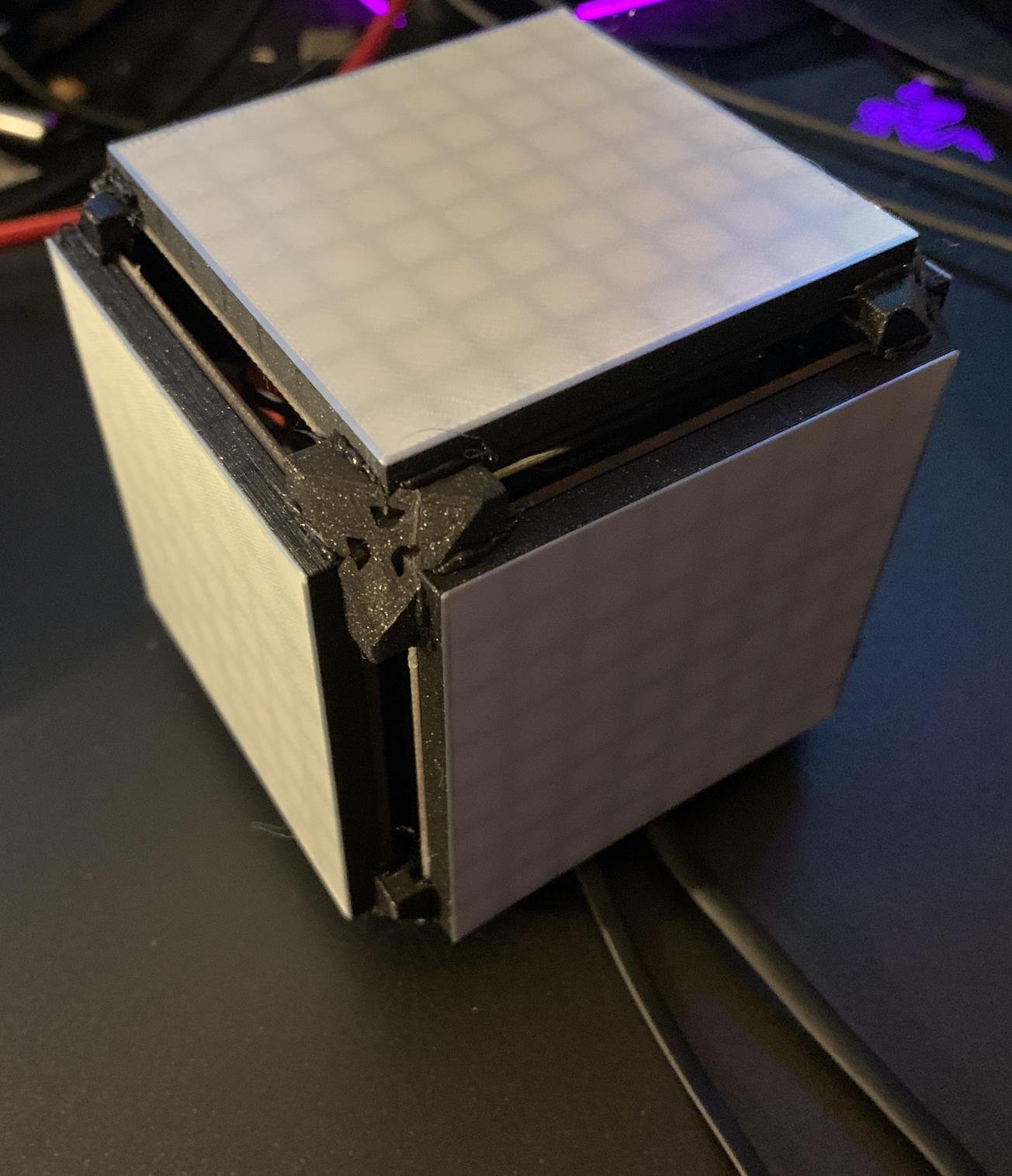

Can You Make a Pixelblaze Cube? Yes!

You too can make a 3D cube, check out BanhammersWrath’s 8x8 WS2812 LED Cube Hackaday project guide.

You can get the corner clips here for 3D printing:

See the guide above for the diffusers and more!

We’re planning cube kits for the future, and will release a slick 3D printable base as well (seen in some of the above videos).

LED Manufacturing

We’ve been building stock of our 8x8 panels this last week. There’s some important details that go in to making good LED products.

These addressable LEDs are WS2812 compatible (also known as SK6812, or NeoPixel). There’s a small IC inside each RGB LED housing that has all the smarts for driving the LEDs at a constant current, and using Pulse Width Modulation (PWM) to control brightness. They accept data in by interpreting a series of short or long pulses, or an absence of any pulses to reset, and forward this data on to the next pixel in line.

What many folks don’t know is that these are extremely moisture sensitive and can easily be damaged when heated up to soldering temperatures. These smart LEDs sometimes get a bad reputation, but more often than not, they aren’t to blame for their faults!

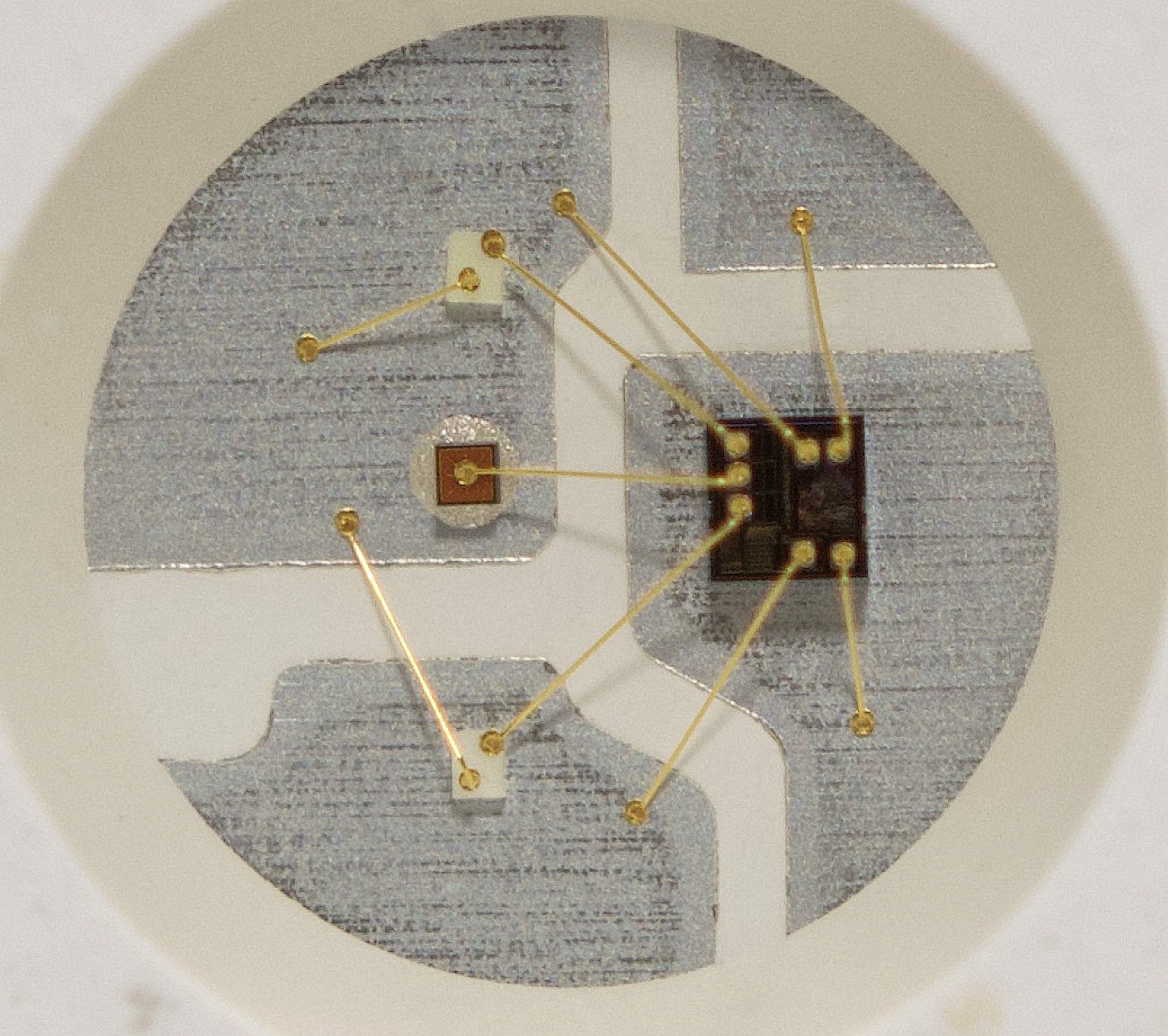

Here’s a good SK6812 (WS2812 clone). Notice that the clear epoxy is completely transparent without any distortions or fractures, and is completely sealed to the white packaging.

Over time moisture in the air will absorb in to the clear epoxy fill or "lens" of the LED. This can happen in just a few hours! When heated to soldering temperatures, this moisture can rapidly expand, causing damage! Like evil popcorn ruining the show.

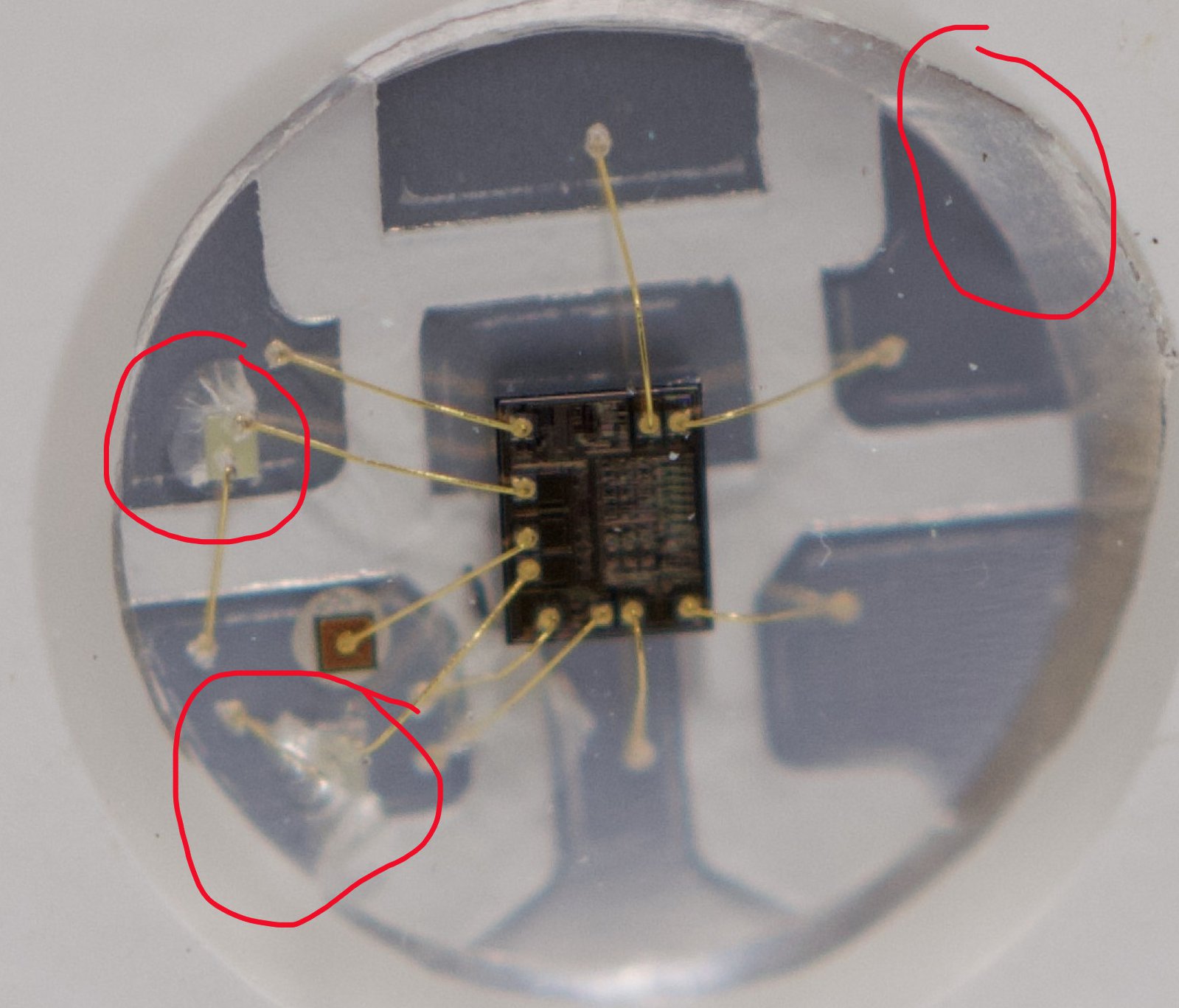

Here’s a bad SK9822 (APA102 clone). Notice fractures cause light reflections where there shouldn’t be, like cracked ice. The seal between the package and the lens has also been compromised!

Damage caused by this can break or weaken the small bond wires. Sometimes one color goes out, sometimes the data input or data output will be the thing to go.

The worst part is that the LED may work fine in testing and the damage may manifest itself months later after you install it, as the compromised seal allows moisture in and causes corrosion, or temperatures changes over time cause small expansions or contractions in the materials and cause the bond wires to separate.

LEDs aren’t the only component that is moisture sensitive, and often these components have special handling requirements and are shipped in vacuum sealed foil packages with desiccant. Some LEDs require baking at specific temperatures for DAYS and then require being placed and soldered within a few hours of exposure to air!

We’ve seen too many issues with cheap LEDs, even with contract manufacturers, which is why we took something as simple as the 8x8 LED matrix in house to manufacture. We hope you appreciate the quality we bake-in!