We set out to create a motor control scheme to address the dynamic needs and demands of the research robots that are developed and used by the Personal Robots group at the Media Lab and other robotics developers around the globe. After years of iteration and experience, the result is the MCBMini v5, a full-featured, scalable, and open source motor control solution.

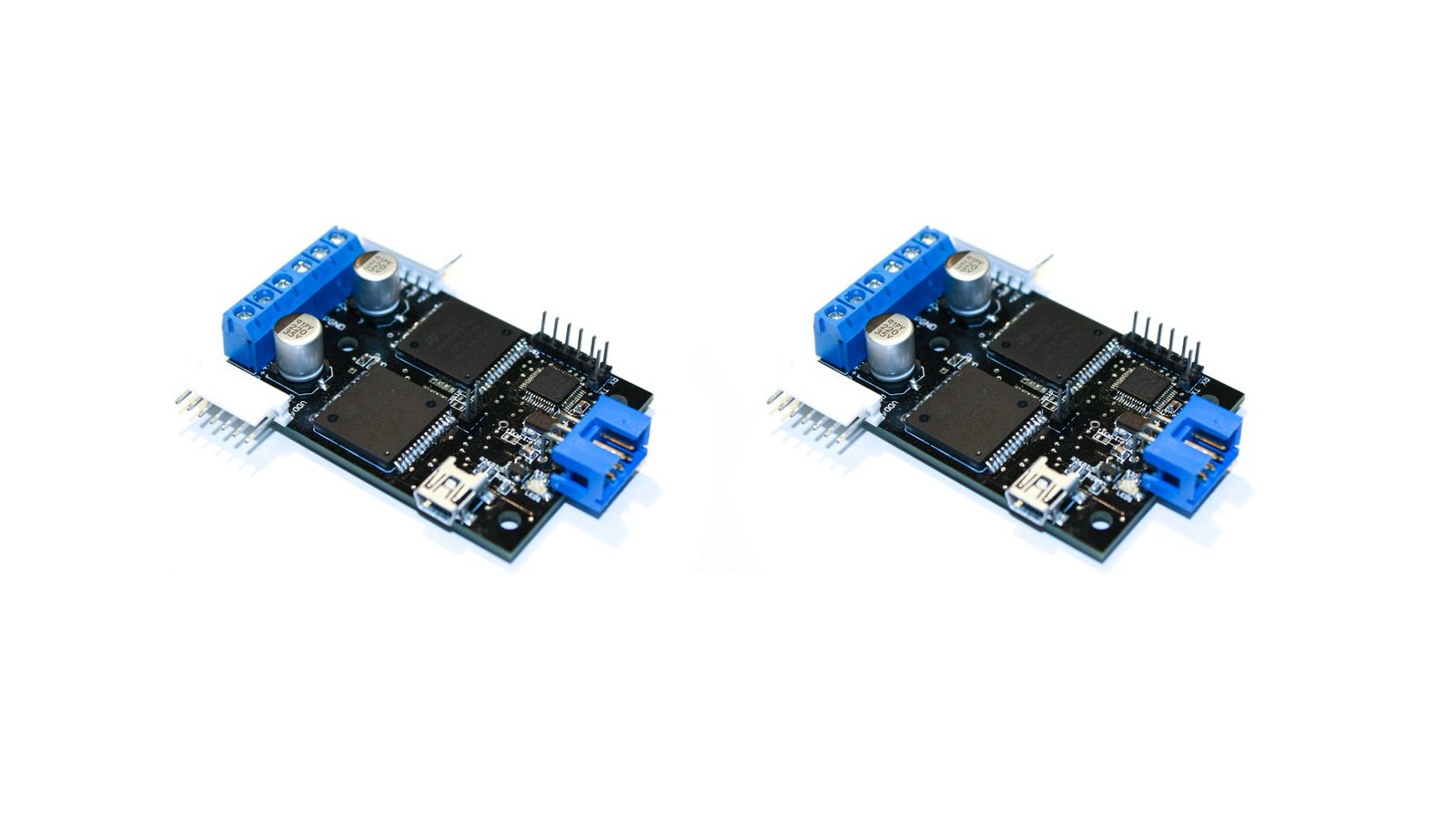

The MCBMini v5 is a single circuit board that provides two closed-loop motor control channels (which could be combined to control one larger motor) with analog or quadrature feedback options, five analog pins for switch/analog input, and both TTL level serial and USB communication interfaces. The boards can be connected together to share a single communications bus to control many motors independently in a streamlined fashion.

MCBMini v5 is the next generation of the original MCBMini project. Improvements include:

The videos below are demonstrations of how the original MCBMini boards can be used. The MCBMini v5 boards are enhanced versions of the boards shown in these videos. vimeo: 76356553

There are many motor controller boards out there. Here’s what sets the MCBMini v5 apart:

Top of the MCBMini v5 board: {img-1846}

Bottom of the MCBMini v5 board: {img-1863}

Each board has two motor control channels, each spec is "per channel" but each board can also be run in "joint" mode where two channels can be used to control one (beefy) motor.

The controllers are expected to be communicated with via Java API but a graphical application is provided as demonstration and for debugging and tuning purposes.

This is the main motor target window where a user can specify motor target positions or velocities and observe instantaneous feedback values.

In this window the user can specify various parameters for the boards and change them on the fly. These parameters are read from a configuration XML file.

In this window the user can observe target and actual values for all the controllers. This is often crucial to tune the controllers for different setups.

This is a screen capture of the software being used in the first video at the top of the page. vimeo: 76728052

This project contains three different kinds of licenses:

All assembly will be performed by a professional fabrication company we’ve been closely working with. The printed circuit boards have already been tested and verified to work.

Because this is a revision of a well-tested board, there is always some chance of some bugs creeping in. It should also be noted that this board is an open source development project so its design and firmware is an ongoing project. We have tested the hardware of the boards and feel comfortable with their performance and as we gain experience with the firmware we will release bug fixes as we come across them. New firmware can be conveniently flashed to the boards via USB.

Produced by Siggi in Cambridge, MA.

Sold and shipped by Crowd Supply.

You’re a supporter of MCBMini v5. Thank you!

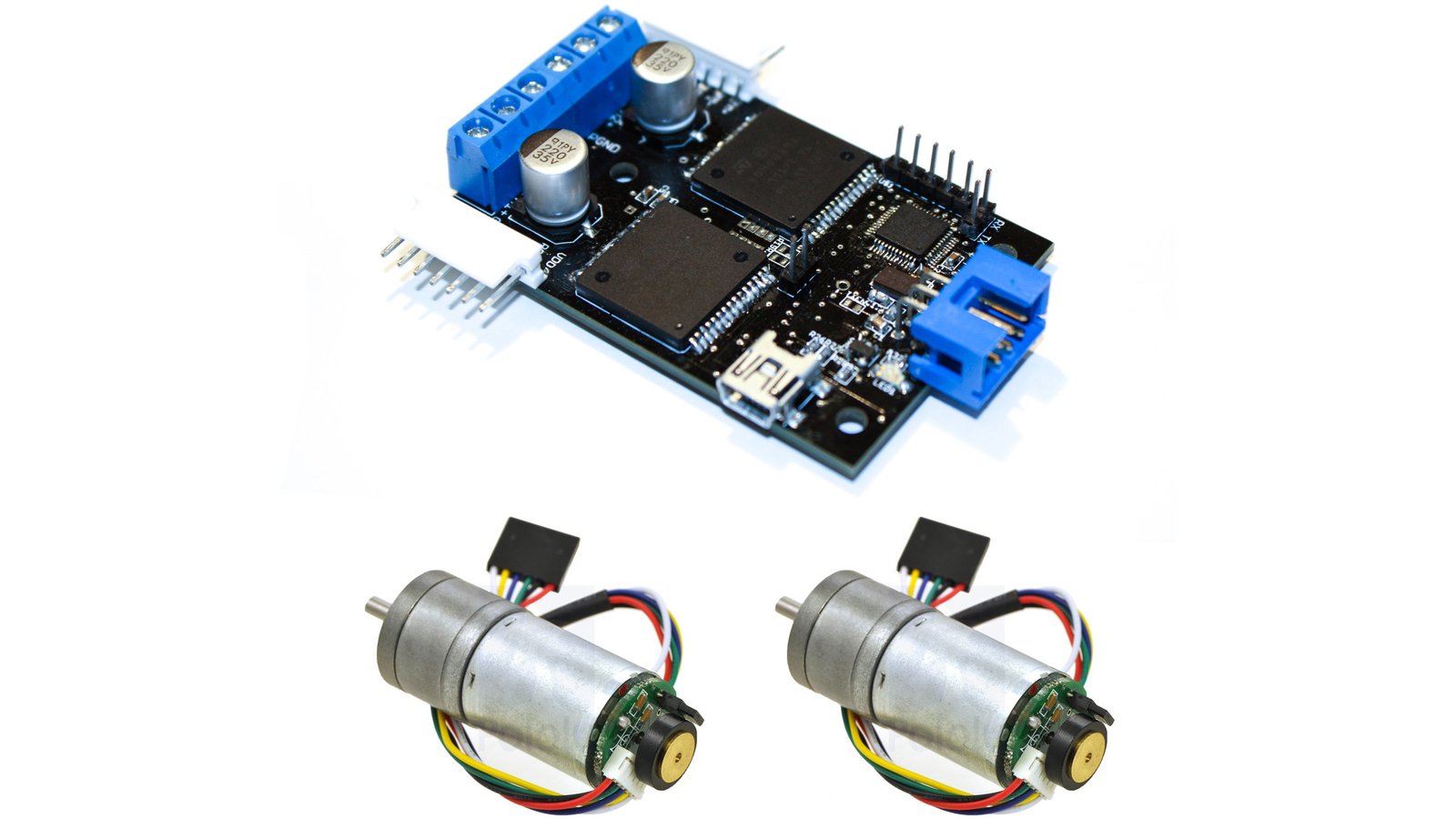

Receive one MCBMini v5 motor controller.

Receve one MCBMini v5 and a pair of gearmotors which are well suited for use with the MCBMini v5. A great foundation for a robot arm, XY table, or other similar projects. The gearmotors are 34:1 with a 48 CPR encoder, sourced from Pololu.