Project update 2 of 17

Updated Kryptor board v1.4

by Piret UustalTime has been flying since our previous post, but we are ready to share some really good news with you.

In our last post, we mentioned some of the changes we planned to make on the Kryptor board. Two of those changes were moving from a 2- to a 4-layer PCB to prepare the board for passing the electromagnetic compatibility (EMC) testing required to get the CE marking of conformity, and changes on the JTAG physical interface that would ensure the smallest PCB footprint. We are happy to say we have accomplished all of that and much more. Read on to see how the new improvements will benefit you.

Benefits of the new Kryptor board

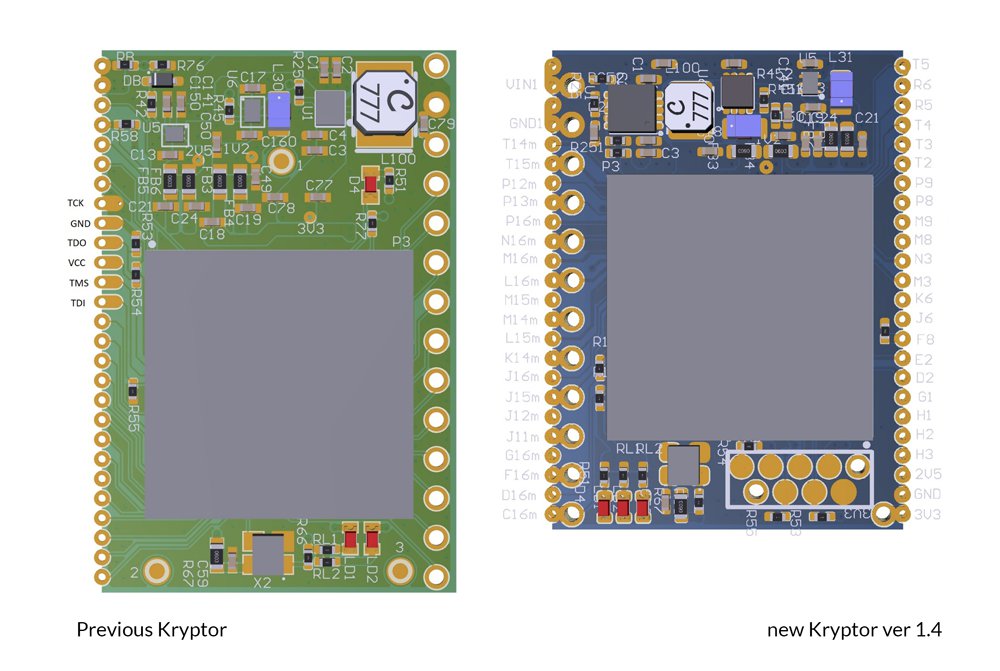

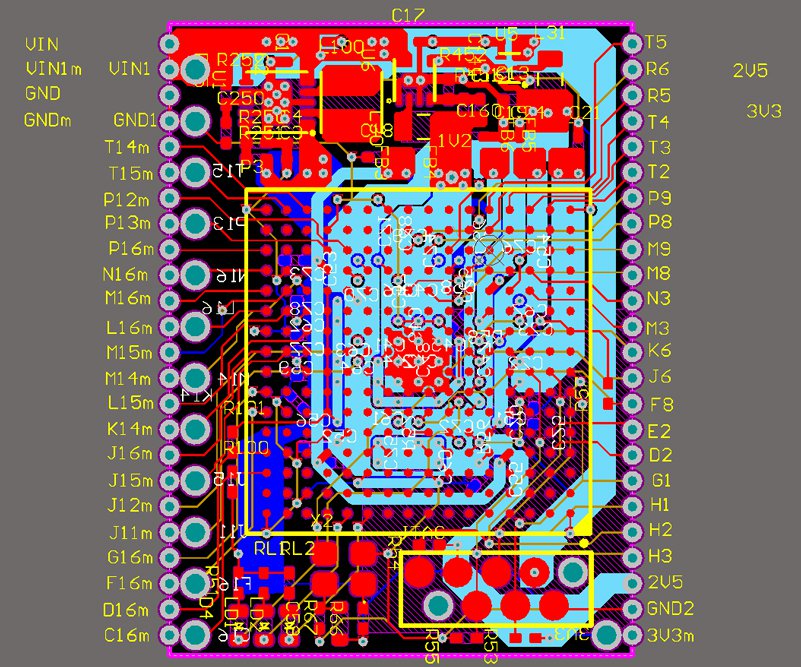

The following images show how the layouts have changed between our previous Kryptor and the new Kryptor ver 1.4.

The new Kryptor board is an evolution of the previous board and represents the final design that will go into production. The set of changes to the new board’s features positively affects many aspects of its usability, flexibility, efficiency, and safety.

Smaller size: Since the final size and weight of the products that can utilize Kryptor (e.g., drones and IoT) is very important, we have packed the new Kryptor as efficiently as possible to decrease its size to 22.8 x 31.2 mm, saving about 4 mm in length.

Castellated pads on both sides: We have added castellated pads to both sides of the PCB, allowing a much greater amount of available GPIO (when used as an SMD board). Plus, it is also more robust when soldered on the host board.

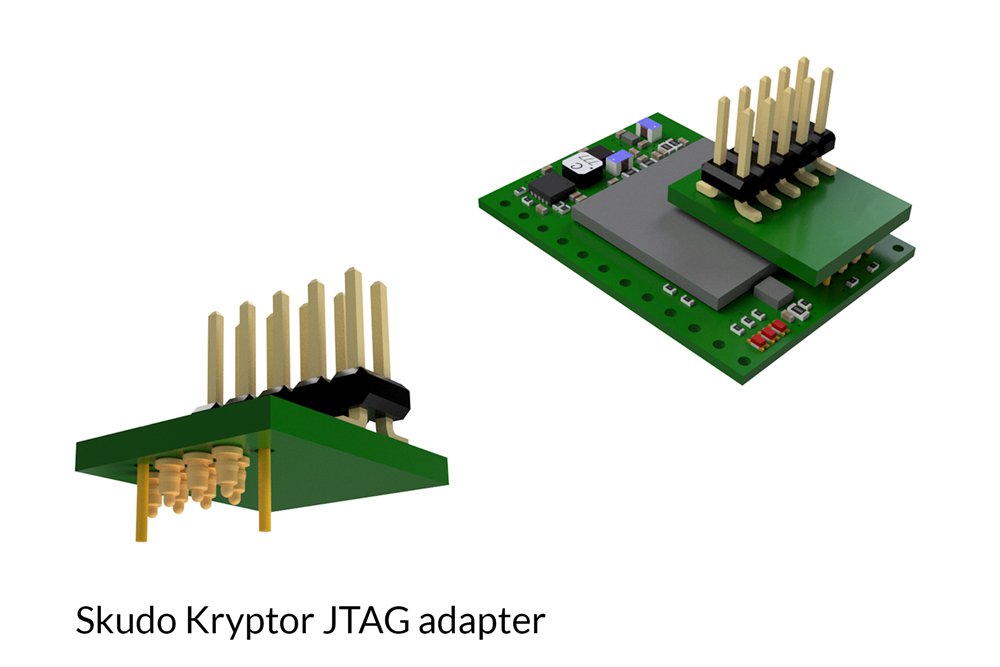

Completely new JTAG mechanism: We have developed a completely new JTAG mechanism for programming the FPGA. This time we abandoned the SOIC-16 clip connector (which was connected to the six longer pads on the side). We adopted a custom-built adapter using tiny pogo pins (see the image below), which terminate the JTAG to a standard IDC 2x5 pins full-size connector. We aimed to improve the design of the JTAG so that it would allow access to program the board both from the top and from the side. This change opens up greater possibilities on the design of the enclosure of the PCB and improves the user experience. It is now more reliable and easier to use, and allows programming when soldered on a host board.

- Ready for EC certification and marking (having four layers): The board is now built on four layers instead of two. The design has been completely redone (ground planes, routing, etc.) to comply with the EC certification and marking tests requirements.

Added features: There are now three LEDs on the bottom left side of the PCB, which can be used by any custom design in the FPGA. Furthermore, one side of the PCB has a full pin header pre-soldered (as in the previous version), facilitating the connection with any breadboard, RPi or Arduino boards. On the bottom right side, there is a single pin for the 3V3 reference voltage, which is not pre-soldered, allowing the users to decide if it is needed or not in their projects.

Less expensive to produce: The new changes will slightly reduce the price of Kryptor through savings in manufacturing costs.

What’s next

Our team is working continuously to make Kryptor available as soon as possible and bring it to you with the highest quality possible. Our next steps include producing a small batch of new Kryptor boards and JTAG connectors to test their performance and quality even further. Additionally, we plan to go through EC certification and laboratory testing with this latest version of Kryptor.

We are also continually researching and testing interesting new applications where you can use Kryptor and will demonstrate those to you in our upcoming newsletters.

To engage with you directly and more frequently, we welcome you to join us on our Telegram group or Twitter account @SkudoTech. And as always, we are happy to hear from you. Your feedback and suggestions for our project are important. So, please be sure to share them with us.