Project update 6 of 14

Countdown to Launch

Key Switches

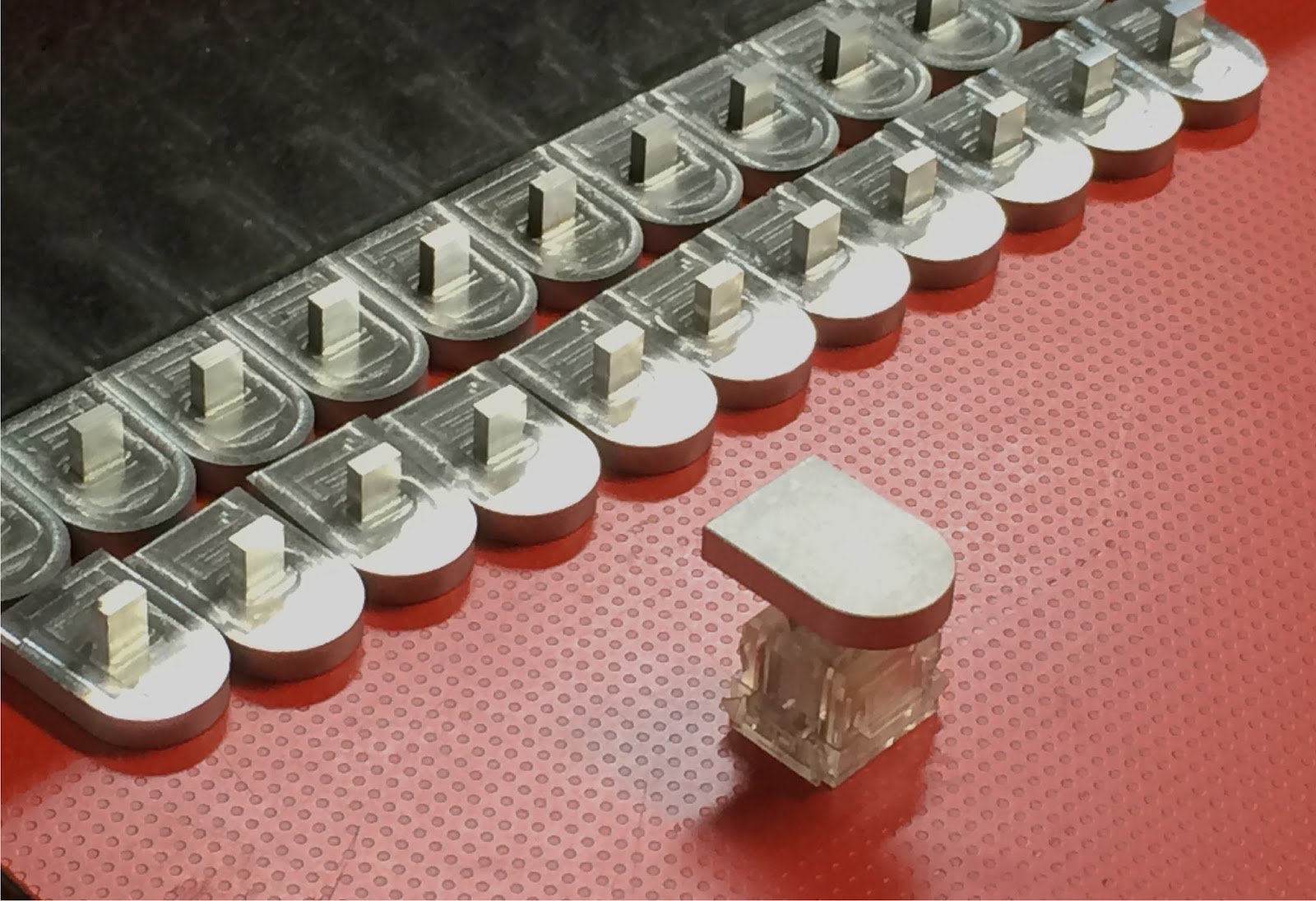

Matias sent me a keyboard with candidates for the final key switch that will be used in the Stenosaurus. I played with it a bit and then sent it to Mirabai. We both independently chose the same candidate, which was convincing enough that I gave Matias the green light to start production. The key switches should be ready in January or before. The switch we ended up going with will have an activation force of approximately 35g, which is one of the lightest activation forces of any mechanical keyboard switch. It may even be the lightest activation force, though I haven’t done an extensive survey. As a point of comparison, the lightest activation force for Cherry MX series of key switches is 45g.

Case and Key Cap Manufacturing

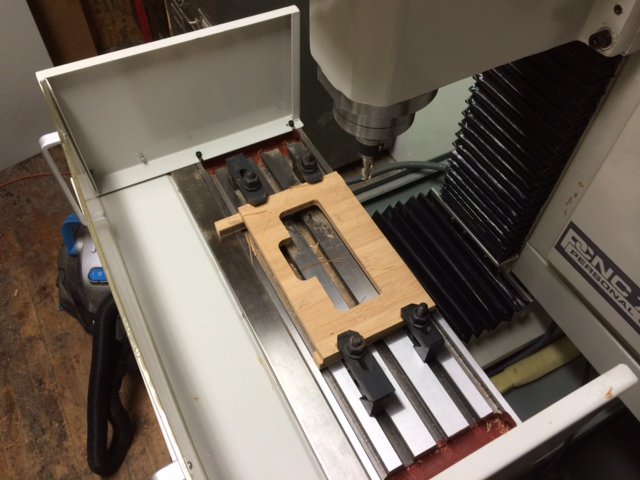

Kurt recently purchased a nice 3-axis CNC mill that he’ll be using to manufacture at least the first batch of production cases and key caps.

Printed Circuit Board Design

Inside the case will be the printed circuit board (PCB) onto which will be mounted all the electrical components of the Stenosaurus, from the USB connector and key switches to the microcontroller and LCD screen. I’m using KiCad for all the PCB design work. This is my first time using KiCad and I’ve been very happy with it so far - it’s free and open source like Plover and the Stenosaurus and, fittingly for a stenography project, KiCad puts a strong emphasis on efficient use of the keyboard by providing consistent and memorable keyboard shortcuts across its entire suite of tools.

I finished the schematic capture and I’m now working on the board layout. Once the layout is complete, hopefully by the end of this week, I’ll work with a PCB manufacturer to get the first boards back for testing. If all goes well, those boards will become the first full-fledged Stenosauruses. If all is not well, then we rinse and repeat.

To Market We Go

Once the PCB has been validated, we will have everything we need to start taking orders via a Crowd Supply campaign. I would love for that to happen before Thanksgiving, but it’s premature to put an exact date on it. Certainly, though, everything is falling into place.