Project update 2 of 4

D-MARK 101! Fun Facts and How To Build Your Own Reflow Oven

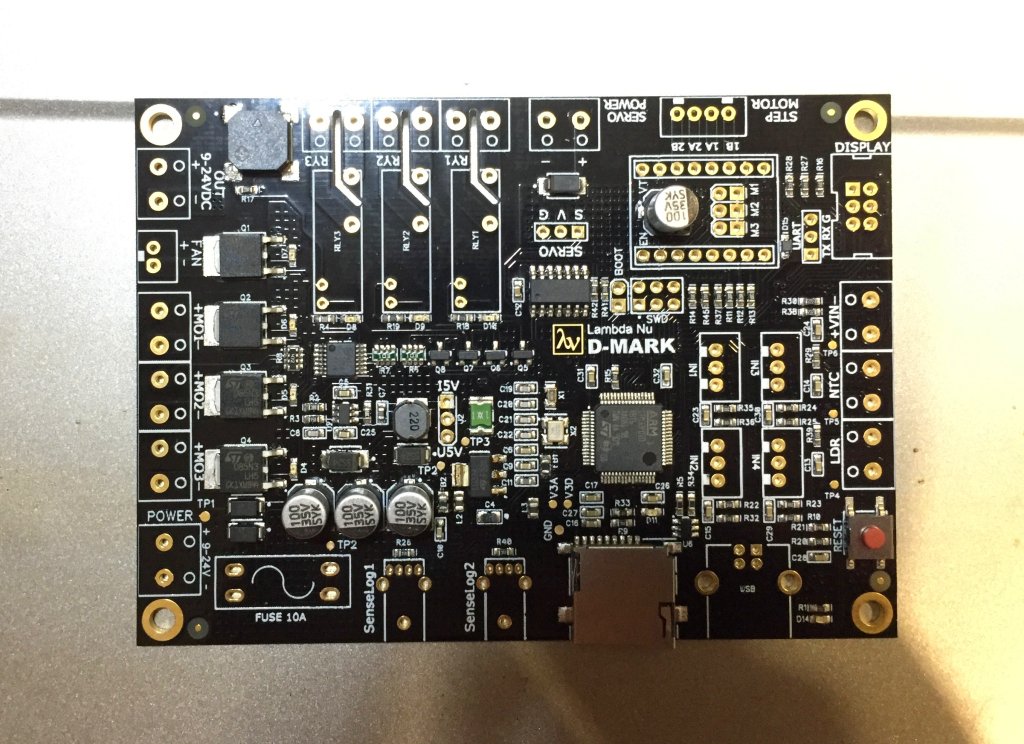

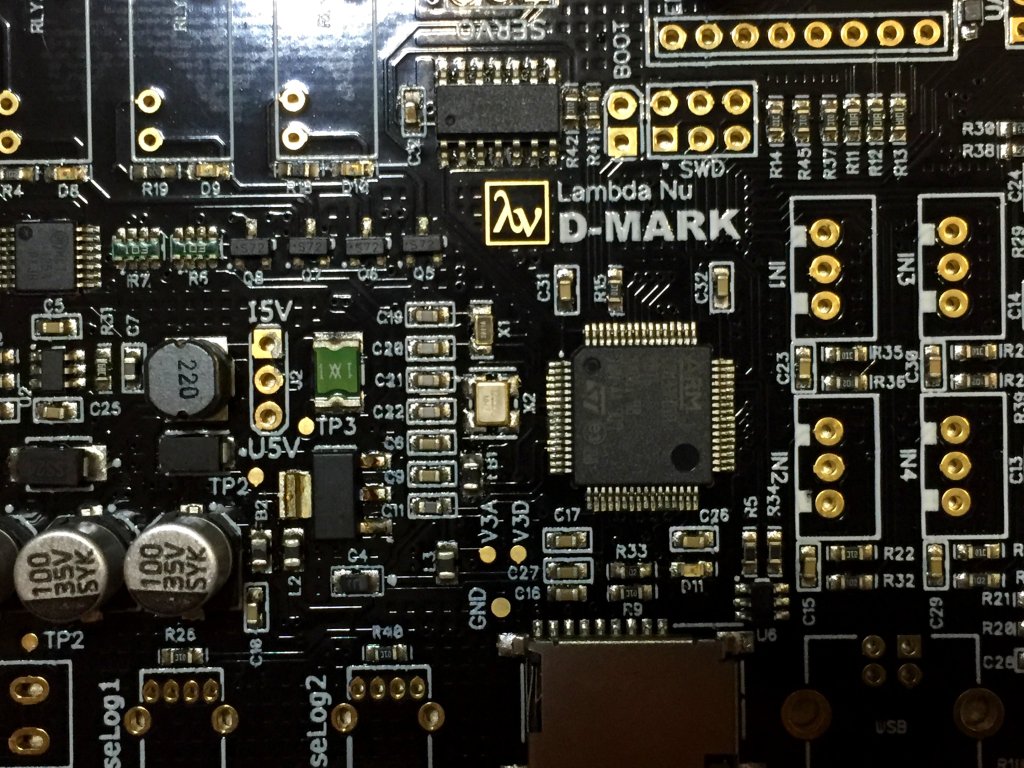

by Dr. KluiFun fact about D-MARK, 101 is actually the total number of board parts! Now, before we get into our first real-world application, here are some more fun facts about the board name.

- It relates to my son's nickname, who was born in Germany, which at the time was still using the Deutsche Mark as its currency.

- It means "Very Good" in the Thai language!

Let’s start with an example to get you familiar with D-MARK, and with using its powerful built- in D-MARK Script (DMSi).

How to Run a D-MARK script

Simply save the script below in a text file named "DMS.txt" on a microSD card and push the reset button once. That’s all!

Example 1: Making Your Own Toaster SMD Reflow Oven

You can buy a cheap reflow oven for SMD soldering these days, but I believe you’ll like this option even more. Just one important note: please don’t use it for cooking your food again!

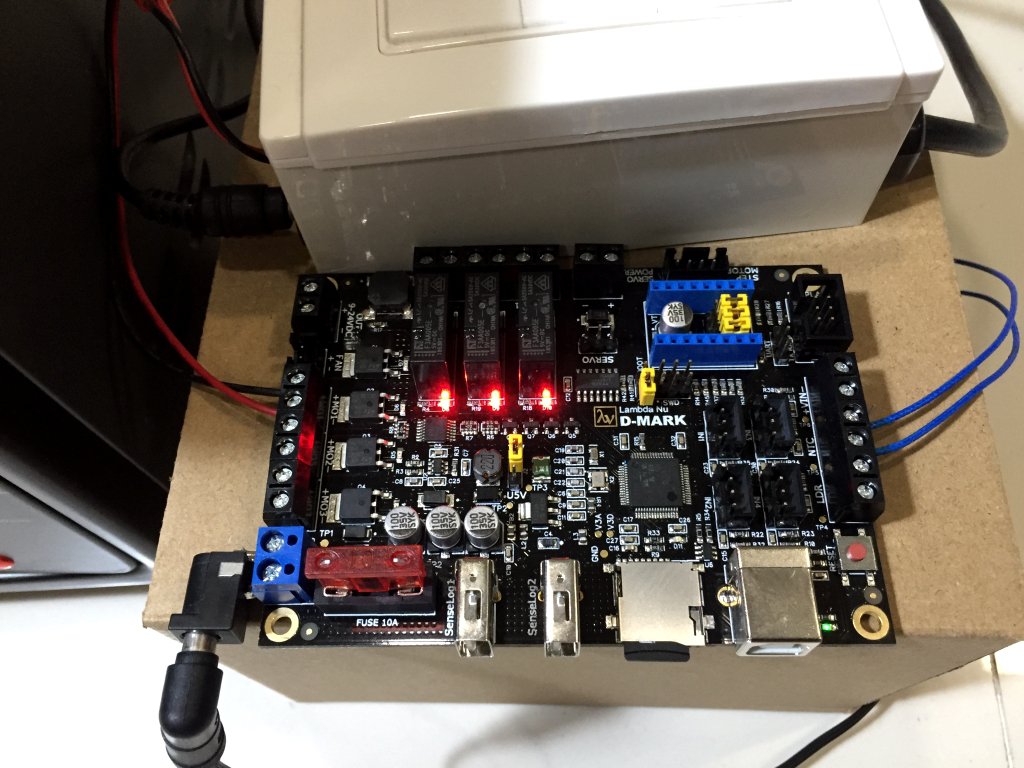

D-MARK Setup:

- Input: A popular B=3950, 100 kΩ NTC, used in most 3D printer heaters (we will give you one as a gift!)

- Output: MOSFET output channel 1. which drives the SSR relay connecting to a 1200 W oven

What we will do:

- heat to 120° C (248° F), soak for 180 s (turn off when >115° C (239° F) as the heat will keep rising a bit even after switching off the heater, turn on again when lower than 115° C).

- heat to 150° C (302° F), soak for 60 s (use 145° C / 239° F as a control set point).

- heat to 220° C (428° F), soak for 30 s (use 215° C / 419° F as a control set point).

- turn off the heater.

DM Script: you can download the script file here.

// Let's config what we are using, use tab as a separator for parameter, not space.

// we will calculate in degree F

NTC.unit 1

// we use 100 kiloohm NTC having B value 3950

NTC.constant_r0 100000

//set the B value to 3950

NTC.constant_b 3950

//set MOSFET output channel 1 to digital output mode

mosfet_1.mode digital

// Ready to start our smart toaster reflow controller

//set a label for the first step heating return loop point as "s1"

:s1

//if the NTC temperature is greater than 239 F, jump to routine "s1_soak"

if.ntc.gt 239,s1_soak

//enable the MOSFET output

mosfet_1.on

//as long as the temperature is not reaching our tartget of 240 F, repeat the loop s1

goto s1

//s1_soak staring point

s1_soak:

//start the timer from 0 s

set.t0 0

//set "s1_soaking" as a starting loop point for checking time and temperature condition.

:s1_soaking

//if the soaking time reaches 180 seconds, jump to do the step 2 (ramp to 294 F).

if.t0.gt 179,s2

//If the NTC temperature reaches 240 F, close the step 1 by jumping to "s1_done"

if.ntc.gt 239,s1_done

//otherwise output will still be on

mosfet_1.on

//loop s1_done as long as the condition is valid

goto s1_soaking

//the end point of step 1 as the soaking time reaches 180 seconds

:s1_done

//turn off the output

mosfet_1.digital 0

//loop over the step 1 soaking routine

goto s1_soaking

//repeat the same procedure for steps 2 and 3 using different temperatures and soak time

:s2

if.ntc.gt 293,s2_soak

mosfet_1.on

goto s2

s2_soak:

set.t0 0

:s2_soaking

if.t0.gt 59,s3

if.ntc.gt 293,s2_done

mosfet_1.digital 1

goto s2_soaking

:s2_done

mosfet_1.digital 0

goto s2_soaking

:s3

if.ntc.gt 419,s3_soak

mosfet_1.digital 1

goto s3

s3_soak:

set.t0 0

:s3_soaking

if.t0.gt 29,turn_off

if.ntc.gt 419,s3_done

mosfet_1.digital 1

goto s3_soaking

:s3_done

mosfet_1.digital 0

goto s3_soaking

:turn_off

//when all the steps done, turn off the output

mosfet_1.digital 0

goto turn_off

We Used This Tutorial to Make D-MARK..With a D-MARK!

Now it is your turn to show your reflow results!

Still more exciting examples to come, make sure you back the campaign to get your hands on a board soon!

Dr. Klui