Hello all,

Due to the production process moving a bit slower than expected, as well as chasing accessory parts, we were not able to meet the target date (April 15) for shipping Ten64. The new timeframe is May 21, 2021, plus/minus a few days.

All Ten64 boards destined for campaign backers have been built and are currently undergoing final test and assembly in the factory. As this is being coordinated remotely it is moving slower than usual (for example, sample units have to be sent overnight for QA approval rather than being approved by us on-site), however, the build process has been running quite well so far.

Thanks for your patience - we are very eager to get Ten64 into your hands.

Free ATX Accessories for All Backers

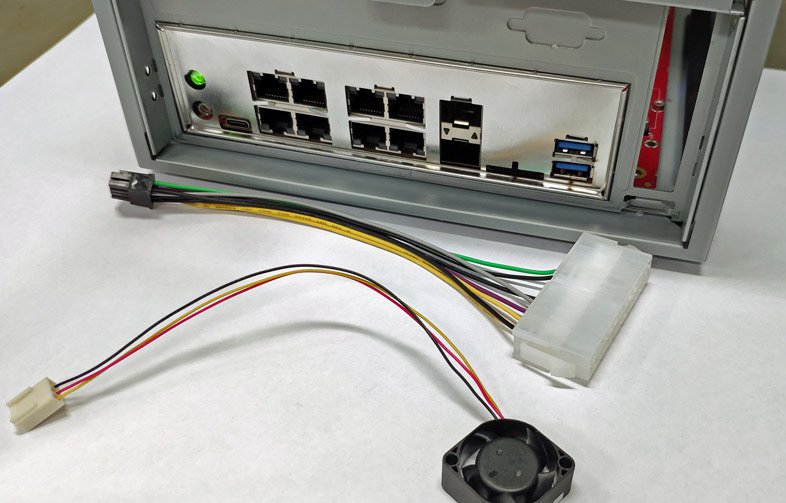

We are happy to announce that all Ten64 purchases through Crowd Supply, both those during the campaign and purchased after will include the required accessories for use in a conventional ITX/ATX case, including the I/O shield, ATX power cable, and a standalone fan for the heatsink. For those that have purchased the "complete kit" SKU currently on offer, this means you can move your Ten64 motherboard out of the desktop case if you wish to do so in the future.

The Ten64 Factory Test Process Explained

We test every Ten64 board end-to-end while it’s in the factory, as is our usual product testing process. They will leave the factory directly to the Crowd Supply warehouse without us physically handling them.

First, the contract manufacturer performs several board-level tests, such as automated optical inspection and flying probe, which do well at catching issues such as opens or shorts.

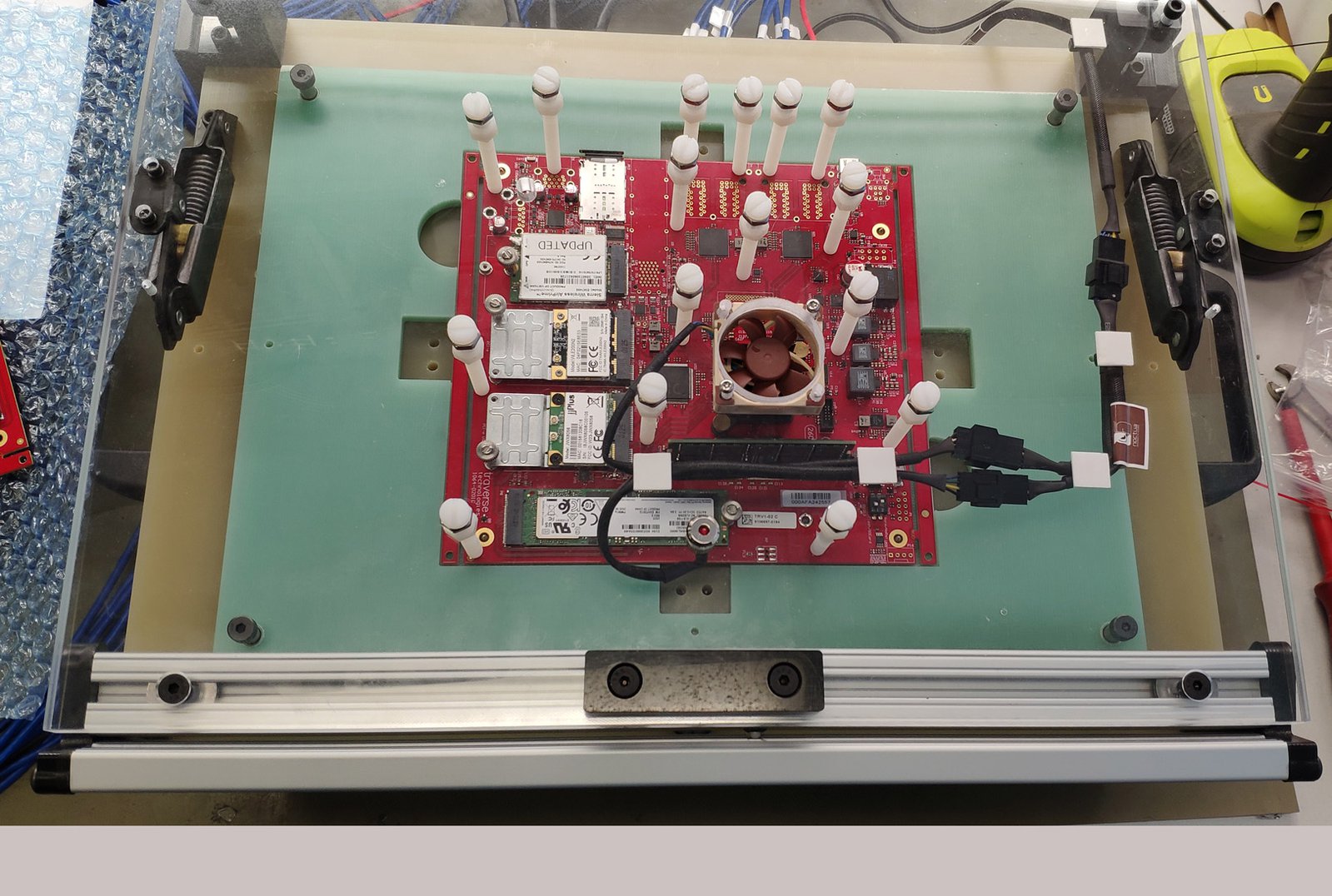

Next come functional tests, for which we use a "bed-of-nails" test setup for the Ten64, which brings up the board and tests its various functions all in a single test cycle, without any manual actions apart from loading/removing the board and inserting sample test cards.

The test fixture brings up all the connections to the board using spring-contact test probes. By physically closing the fixture, the board is pushed downwards by the push rods and contact is maintained with the test probes. The physical fixture itself was a major engineering effort, as the test pins need to align perfectly between the target board under test, through a machined fiberglass plate and mirrored onto a connector PCB inside the fixture. If you are curious to see how a bed-of-nails fixture works mechanically, check out this video of a similar fixture (we use a PCB rather than wires to route the signals).

Notice that the major connectors (Ethernet, SFP+, Power and USB) are not loaded in the test fixture, as we do initial functional testing before soldering through-hole connectors. There are practical reasons for this, one being that using spring-contact pins against loaded connectors isn’t viable with the small pitches on modern high speed connectors. The other reason in the case of the Ten64 is that boards in need of rework are more easily accessed without the major connectors already soldered in place. For example, once the Ethernet connectors are on, it is difficult to rework the Ethernet PHYs without also removing the Ethernet connectors.

The test fixture has the ability to turn power to the board on and off, as well as drive important control lines on the board, like RESET and SD<->Flash boot mode. While in the test fixture, our functional test does the following:

- Program the board microcontroller

- Boot the board from a microSD card and load a test ramdisk over Ethernet

- Inside the test image, run traffic from each Ethernet port (using iperf3), as well as check functions such as PCIe cards, USB 3, sensors, real-time clock, and TPM

- Flash a firmware package onto the QSPI flash and reboot in SPI boot mode

After soldering the through-hole components, we run a similar post-assembly test which occurs with all the Ethernet, SFP and USB 3 ports connected.

This ensures these ports work (and there are no faults inside the connectors themselves) and, in cases where a customer supplies the firmware, we test to ensure the firmware is loaded and functional. For the generic units going to Crowd Supply backers, we test against an OpenWrt image loaded from USB.