Printed circuit board assembly is a critical part of building electronic devices. While high volume PCB batches are normally handled by specialized machines in a factory assembly line, prototypes are often built by hand. Hand assembly is slow, difficult, and extremely tedious, but out-sourcing such work to a factory is rarely cost-effective. And even if it were, it is often infeasible for other reasons:

Investing in a personal pick-and-place machine is one way to address these issues. While not as fast as their industrial counterparts, such machines easily outpace the physically tiresome act of hand assembly. And they do so without breaking the bank. SimplePnP was designed to be reliable, accurate, affordable, and suitable for a wide variety of components. It is a good choice for electronics startups, inventors, researchers, and hackerspaces alike.

By taking advantage of a low backlash timing pulley and a linear rail system, SimplePnP is able to place components accurately. It achieves a step resolution of 10 microns using richly featured Trinamic stepper drivers.

High precision, quick change Juki nozzle holders, from Betz Technik Industries, allow for very low runout, so rotating a part does not affect the held component’s final position. These nozzles are commercially available and can cover a wide range of component shapes and sizes, from a tiny 0402 parts to large modules like shielded wireless radios. (Please note that you will need to find a size 502 nozzle elsewhere, if you need to work with 0402 parts, as the nozzle sets we offer through this campaign do not include one.)

Finally, an HD camera supports the use of computer vision feedback to ensure that every step of the process goes as planned. The top-vision camera verifies board and component alignment fiducials and SMD tape holes to determine specific location coordinates on the machine or PCB. An optional bottom-vision camera identifies linear and angular offsets of picked parts, allowing the machine to adjust each component position before placing it on the board.

Due to its simple construction and open source nature, SimplePnP can be adapted to suit a great variety of applications. You can use the pick-and-place frame just by positioning it on a flat surface, or you can fix it to a workbench by sourcing easy-to-find hardware for the 2020 aluminum extrusion. For maximum stability, you can even mount it directly to a base using linear rails.

SimplePnP accommodates many different types of component feeders. You can purchase basic fixed-tape feeders along with your machine, and component trays just need to be placed inside the pick-and-place work area. You can also fit third-party or DIY drag, vibration, and automatic feeders. OpenPnP’s UI makes it easy to configure and use all of the different feeder options.

Another key feature of SimplePnP is its extensive upgrade-path. We will make several optional extras available for purchase in the near future. The most interesting of these are likely:

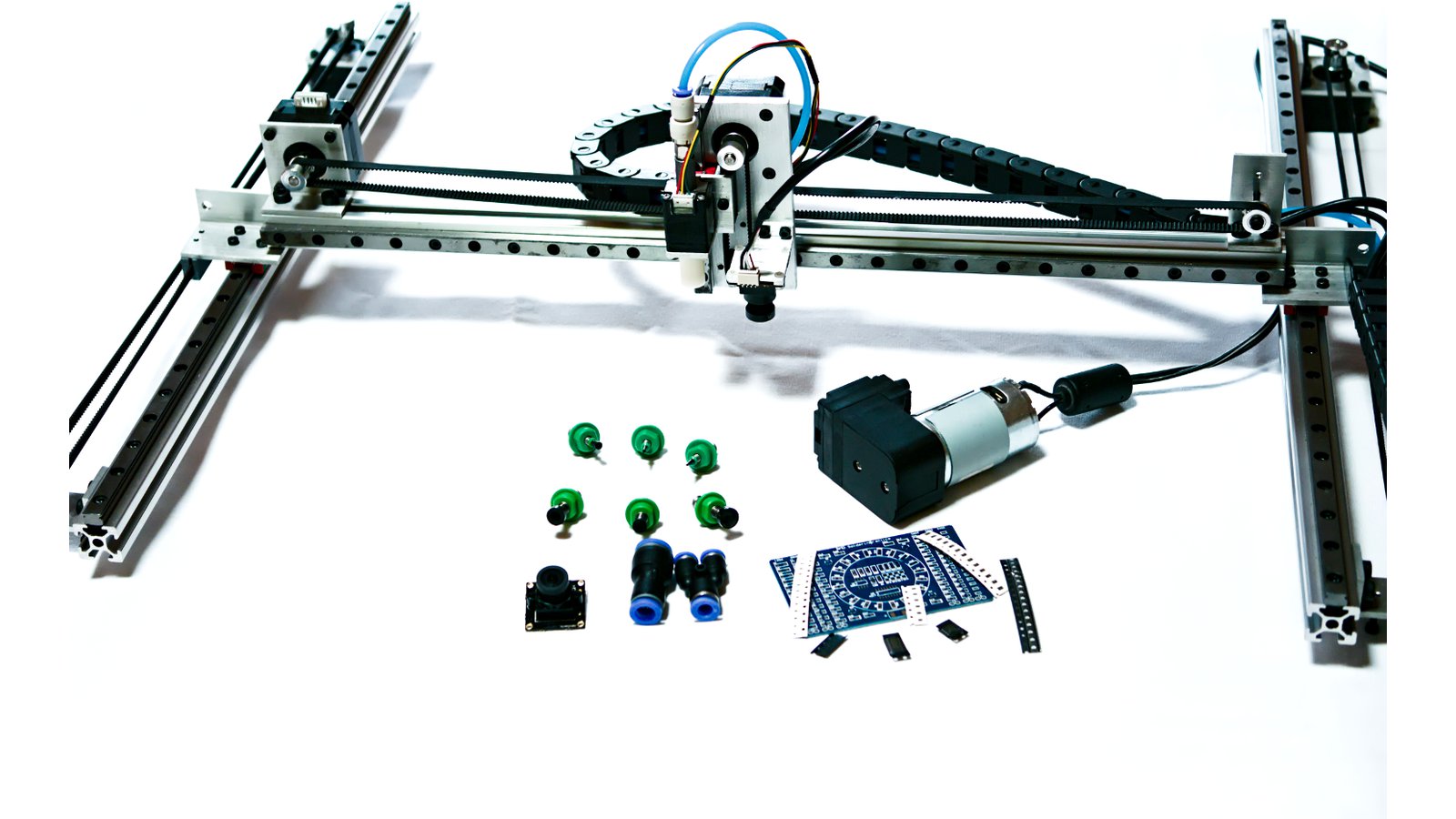

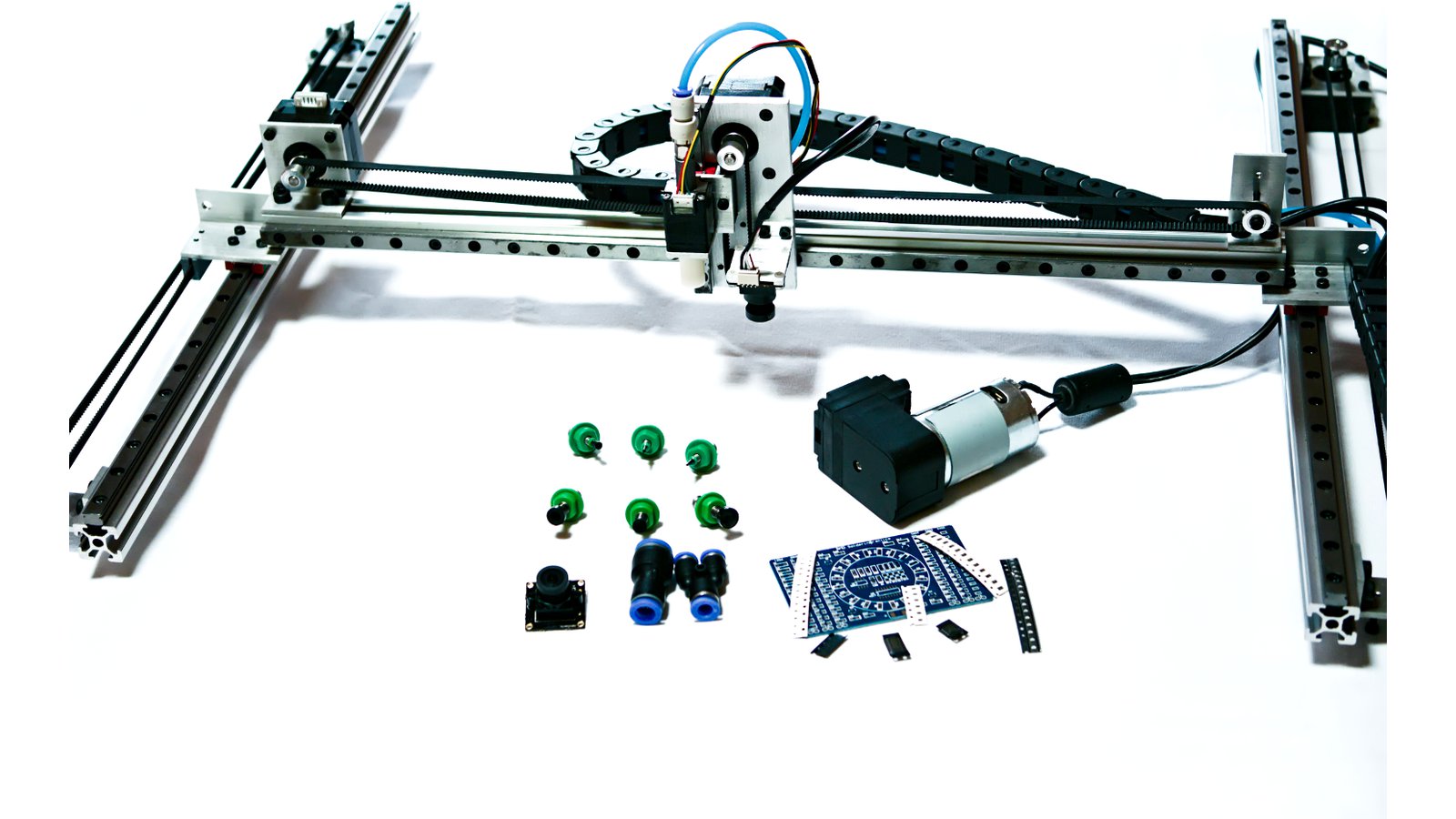

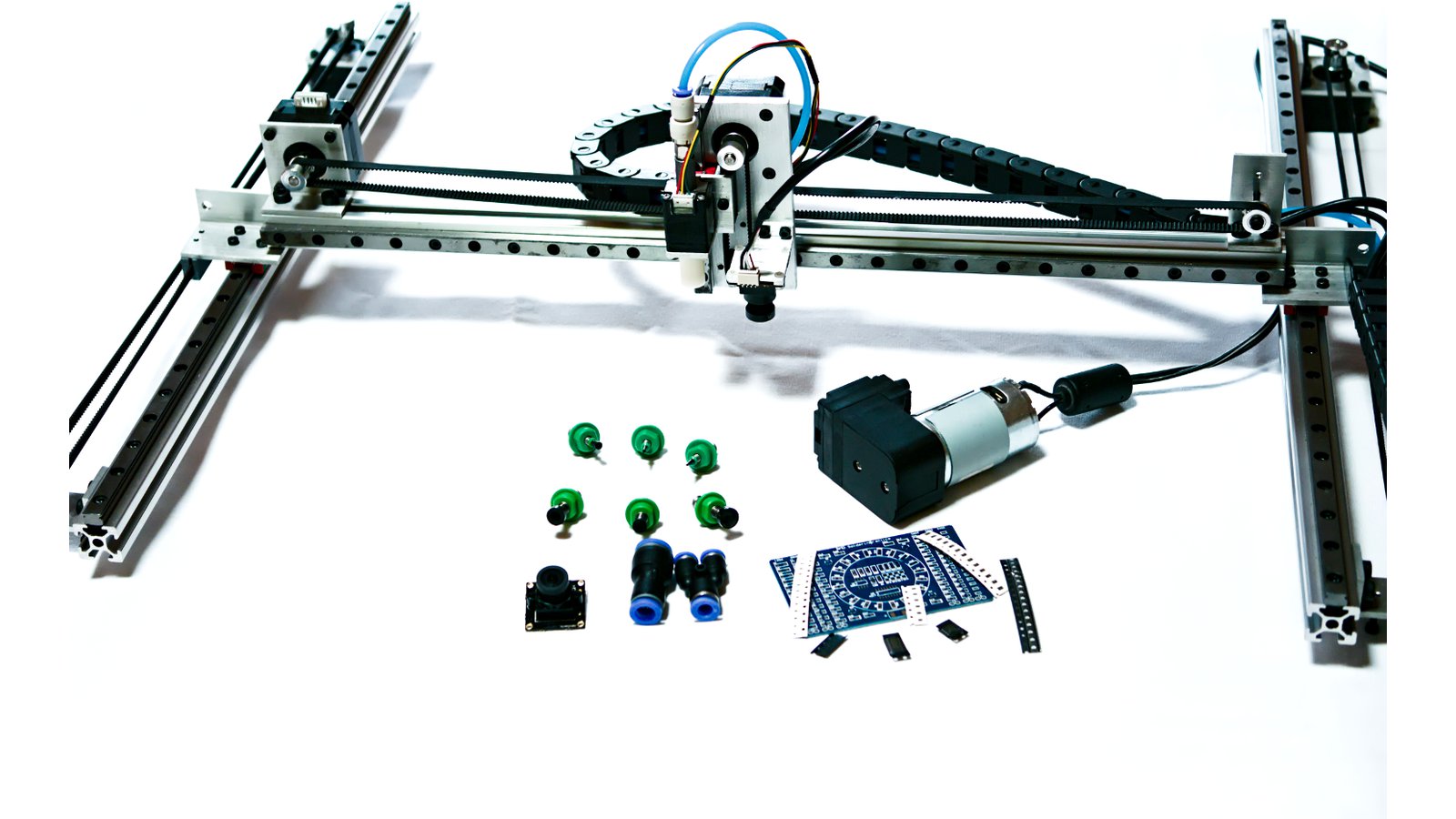

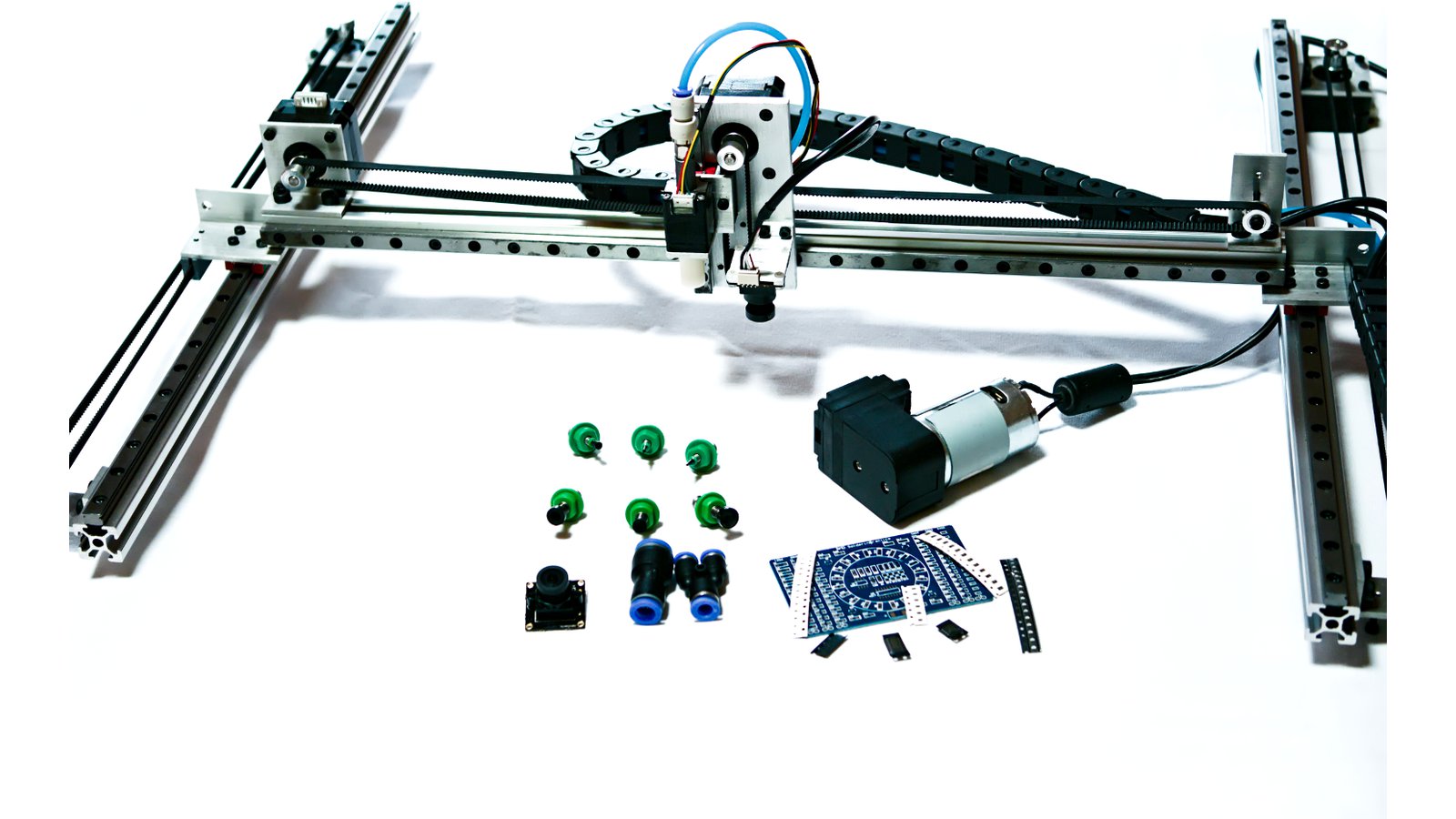

SimplePnP includes two main components: the head and the table.

The head grabs electronic components meant to be installed on a PCB. It relies on a hollow shaft stepper motor to rotate while a DC vacuum pump uses variously sized nozzles to hold parts. The pancake stepper motors are mounted to an aluminum bracket, and a piece of 2020 extrusion couples it together with the linear rail, carriage, and gt2 belt clamp. The vacuum pump provides a working pressure of around -40 kPa with a flow of 10 liters per minute.

Depending on the model, one or two Omnivision OV9712-based 720p USB cameras help locate features and components and adjust component alignment. The vision modules make use of commercially available, manual-focus lenses with focal lengths of 2.8 mm for the top-vision camera and 2.1 mm for the bottom-vision camera.

The table is meant to position the head in the correct spot to hold and release each component. It is a gantry style system built from aluminum extrusion and uses linear rails, stepper motors, and timing belts to perform motion.

A computer running OpenPnP serves as the machine’s brain, sending the appropriate commands to a pair of GRBL motion controllers that handle the operations needed to perform PCB assembly.

| SimplePnP | Liteplacer | CHMT36VA | |

|---|---|---|---|

| Work Area | 300 mm x 300 mm | 570 mm x 370 mm | 355 mm x 355 mm |

| Vision | Yes | Yes | Yes |

| Dual Head | Yes | No | Yes |

| Automatic Nozzle Changer | Available separately | Yes | No |

| Feeders | Tray feeders available | No | Drag feeders included |

| Linear Motion | Linear rails | Roller wheels | Ground Rods |

| Open Source | HW + SW | HW + SW | No |

| Price | $630 USD | ~$1,799 USD plus shipping | ~$2,900 USD plus shipping |

Our official GitHub repository is the most important source of information regarding SimplePnP. It includes our design files, the hardware and software user manuals, and a PDF assembly guide. The OpenPnP wiki is a great place to find documentation on how to configure the control software.

If you have a question about ordering or shipping, please contact Crowd Supply. If you have a question about SimplePnP, please contact us!

As soon as funds are available, we will purchase the necessary off-the-shelf components, along with the parts and raw materials we will need to create the custom components.

SimplePnP’s motor brackets, pulley brackets, and vacuum head plate will be manufactured in aluminum. The component rotation motor mounts, camera mounts and component tape trays will be fabricated in plastic. The nozzle holders will be turned on a CNC lathe by Betz Technik Industries.

Custom form factor motion controller boards need to be ordered so we can assembled them in-house (using SimplePnP) and install them in the machines that will go out to backers.

Once the custom-fabricated parts are done, they’ll be sent in bulk to Crowd Supply along with the rest of the items. From there, SimplePnP kits will be shipped to backers. (For more information, please see Crowd Supply’s ordering, paying, and shipping guide.)

We have done a lot of work to ensure that our design uses materials and parts that can be sourced from several providers. As a result, there is little risk that we will have to make modifications down the line due to sourcing challenges.

The parts and electronics used in SimplePnP are very easy to manufacture, so setbacks due to manufacturing errors are also quite unlikely. As always, product delivery slow-downs caused by shipping delays remain a possibility.

Rest assured that we will update you regularly on our progress.

"Citrus CNC took notice of how expensive these machines can be and set out to design a PnP platform for prototyping boards that costs about as much as a hobbyist 3D printer"

"You’ll find the design files, hardware & software user manuals, and a PDF assembly guide on Github. You can also read the instructions to configure OpenPnP control software working on Mac OS, Windows and Linux."

Produced by Citrus CNC in Mexico City, Mexico.

Sold and shipped by Crowd Supply.

A partially assembled Cartesian frame with extrusions, motors, rails, mounting hardware, pulleys, and belts. An assembled vacuum head with one nozzle holder, a top-vision camera, one rotation motor, one linear rail, and pneumatic components. Includes a vacuum pump, a power supply, motion control electronics, and three Juki nozzles (sizes 503, 504, and 505).

A partially assembled Cartesian frame with extrusions, motors, rails, mounting hardware, pulleys, and belts. An assembled vacuum head with one nozzle holder, a top-vision camera, a bottom-vision camera (including mounting hardware and a USB cable), one rotation motor, one linear rail, and pneumatic components. Includes a vacuum pump, a power supply, motion control electronics, and three Juki nozzles (sizes 503, 504, and 505).

A partially assembled Cartesian frame with extrusions, motors, rails, mounting hardware, pulleys, and belts. An assembled vacuum head with one nozzle holder, a top-vision camera, one rotation motor, one linear rail, and pneumatic components. Adds an additional nozzle holder, rotation motor, and linear rail (including mounting hardware). Includes a vacuum pump, a power supply, motion control electronics, and three Juki nozzles (sizes 503, 504, and 505).

A partially assembled Cartesian frame with extrusions, motors, rails, mounting hardware, pulleys, and belts. An assembled vacuum head with one nozzle holder, a top-vision camera, a bottom-vision camera (including mounting hardware and a USB cable), one rotation motor, one linear rail, and pneumatic components. Adds an additional nozzle holder, rotation motor, and linear rail (including mounting hardware). Includes a vacuum pump, a power supply, motion control electronics, and three Juki nozzles (sizes 503, 504, and 505).