Hello everyone!

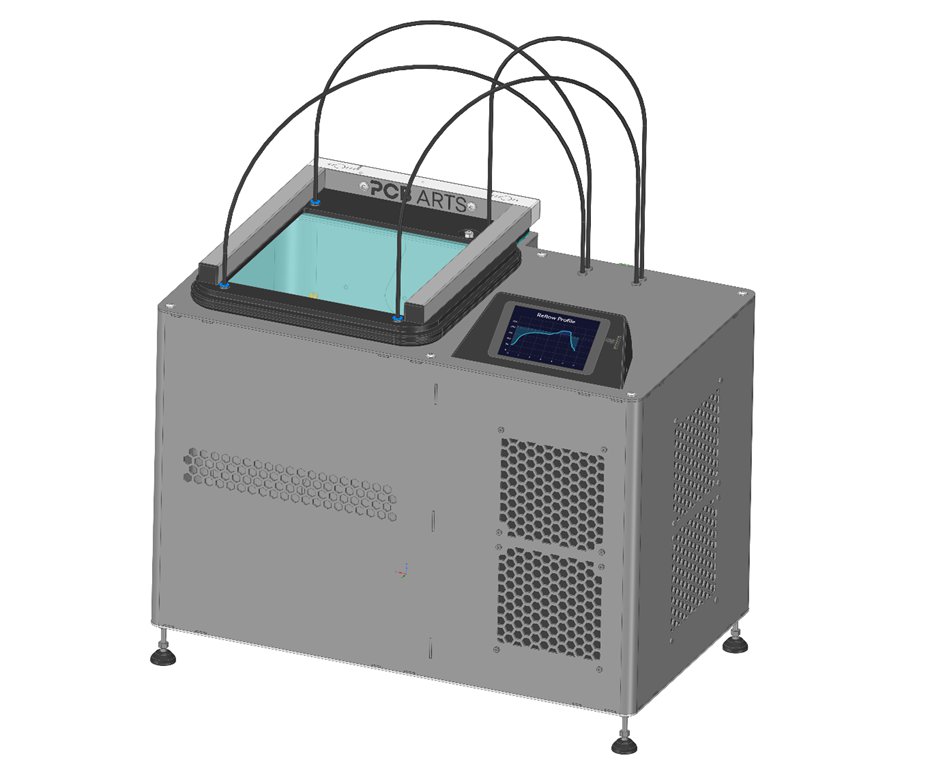

In the last few months we learned a lot about product development. We are in touch with many Vapor Phase One owners. That is how we can record and incorporate feedback actively. We are happy to see our soldering system is well received by electronic developers worldwide!

In the following update, you will find some design improvements and software updates we already implemented or will implement within the year 2022.

Redesign

First, we redesigned our product in terms of manufacturability. While producing the first batch, we noticed the process of assembling the VPO was way too time consuming. It took about eighteen hours to assemble one Vapor Phase One. That is neither optimal nor easy to maintain. Thanks to our redesign we were able to reduce the time for assembling by one third to twelve hours!

We also recognized other important points of improvement while producing the first batch, like choosing the right screws. It is a learning process in many ways indeed.

Producing the second batch

Since our warehouse is empty, we will now start producing a second batch of fifty Vapor Phase One’s. To make that real, we will have to get some improvements post-certified. That is part of the process of establishing a durable and sustainable product in the market. Luckily, we already received pre-orders. So, we are confident in the pre-financing of this more extensive batch. As you can see below, we already purchased a lot of components to get started:

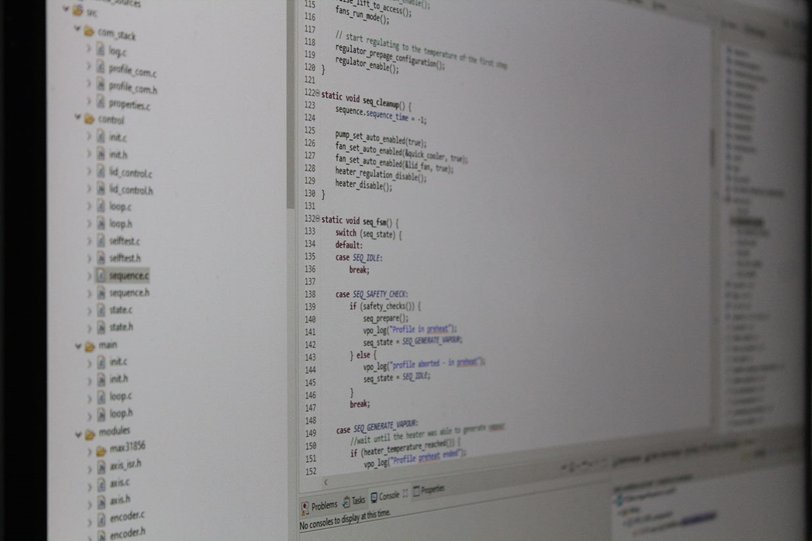

Software Update in 2022

Furthermore, there will be new software updates for the VPO. The soldering machine will support other kinds of Galden after the update. Currently, only Galden with a boiling point of 230°C can be used based on the software. But hardware-wise the VPO is prepared to process different kinds of Galden, which can be chosen in the soldering profile after updating. Another feedback we incorporated is that it would be advantageous to know in which step of the soldering process the Vapor Phase One is in. After the update the display will tell, if the VPO is heating up, soldering, or cooling down just now. There will also be the possibility to adjust whether the “Anti-Condensation-Mode” should be applied. This allows the user to solder their PCBs even more flexible.

We will keep you updated about our process of learning and improving the Vapor Phase One in cooperation with our customers and own experiences. Stay tuned! With best regards from Germany,

Your PCB Arts Team