Hi everyone,

First of all, many thanks for all of the support over the past week!

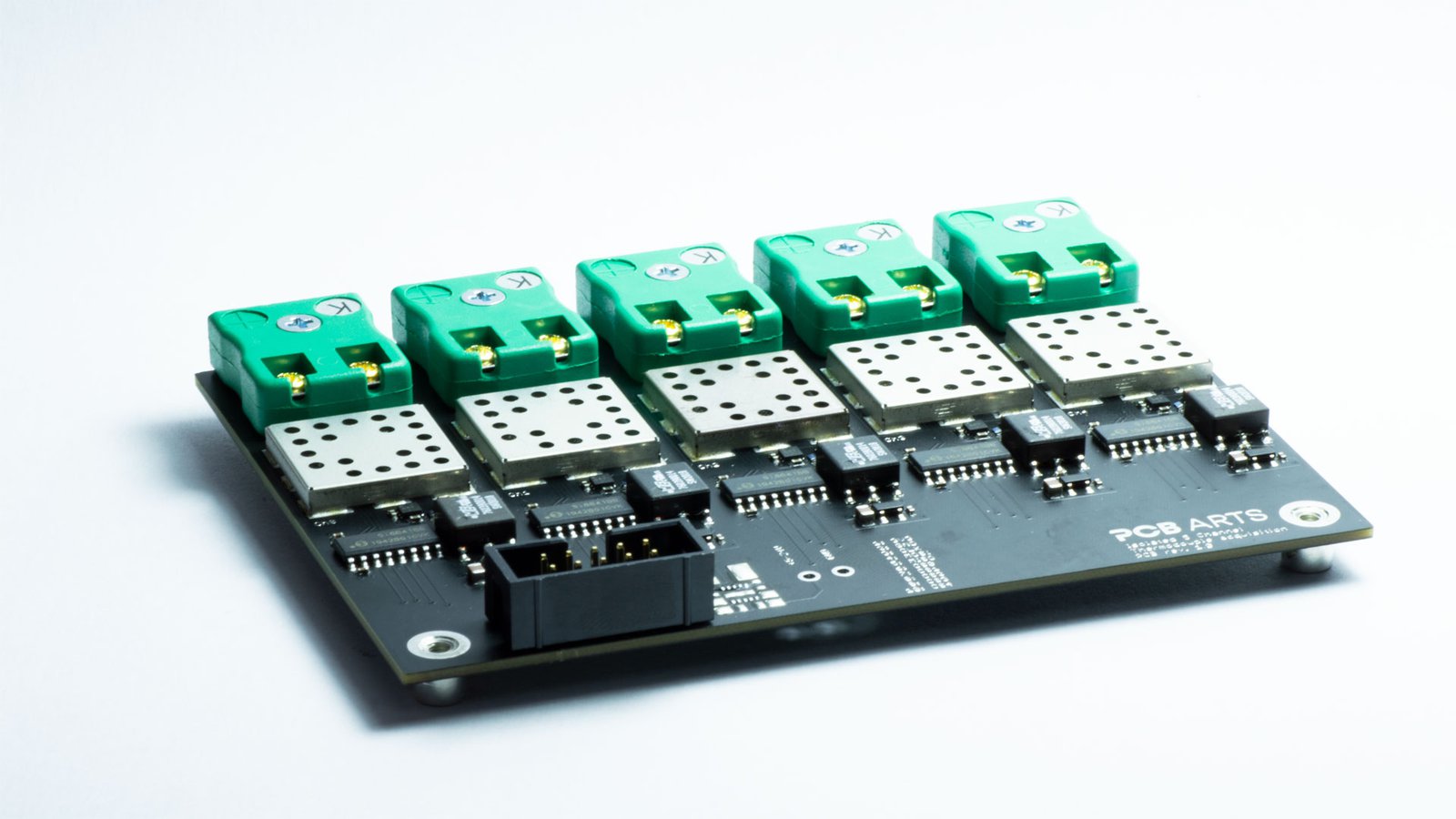

In order to improve the reliability and precision of Vapor Phase One, we decided to design a new isolated temperature monitoring system. The new board consists of five temperature-sensing channels powered by MAX31856s thermocoupled to digital converters. These ICs provide updated temperature data every 250 ms. This comparatively high sample rate allows the PID controller to react to the rapid temperature changes that occur when the lift reaches the actual vapor phase. Thanks to galvanic isolation, the thermocouples can be attached directly to the measuring point without needing to be electrically isolated.

Alongside this upgrade to the thermal performance of Vapor Phase One, we have also made a number of user interface improvements. We decided to add a dedicated controller that handles all communication with the capacitive touch screen. During start-up, it establishes a UART connection to the core vapor phase controller that is responsible for all safety- and timing-critical tasks. In this way, relevant system data can be displayed and the touchscreen can control behavior such as lift operation.

The soldering process can now be started with a single tap:

Many thanks and best wishes from Germany,

The PCB Arts Team