Class B Project

Robotics & Motors

Class B Project

Robotics & Motors

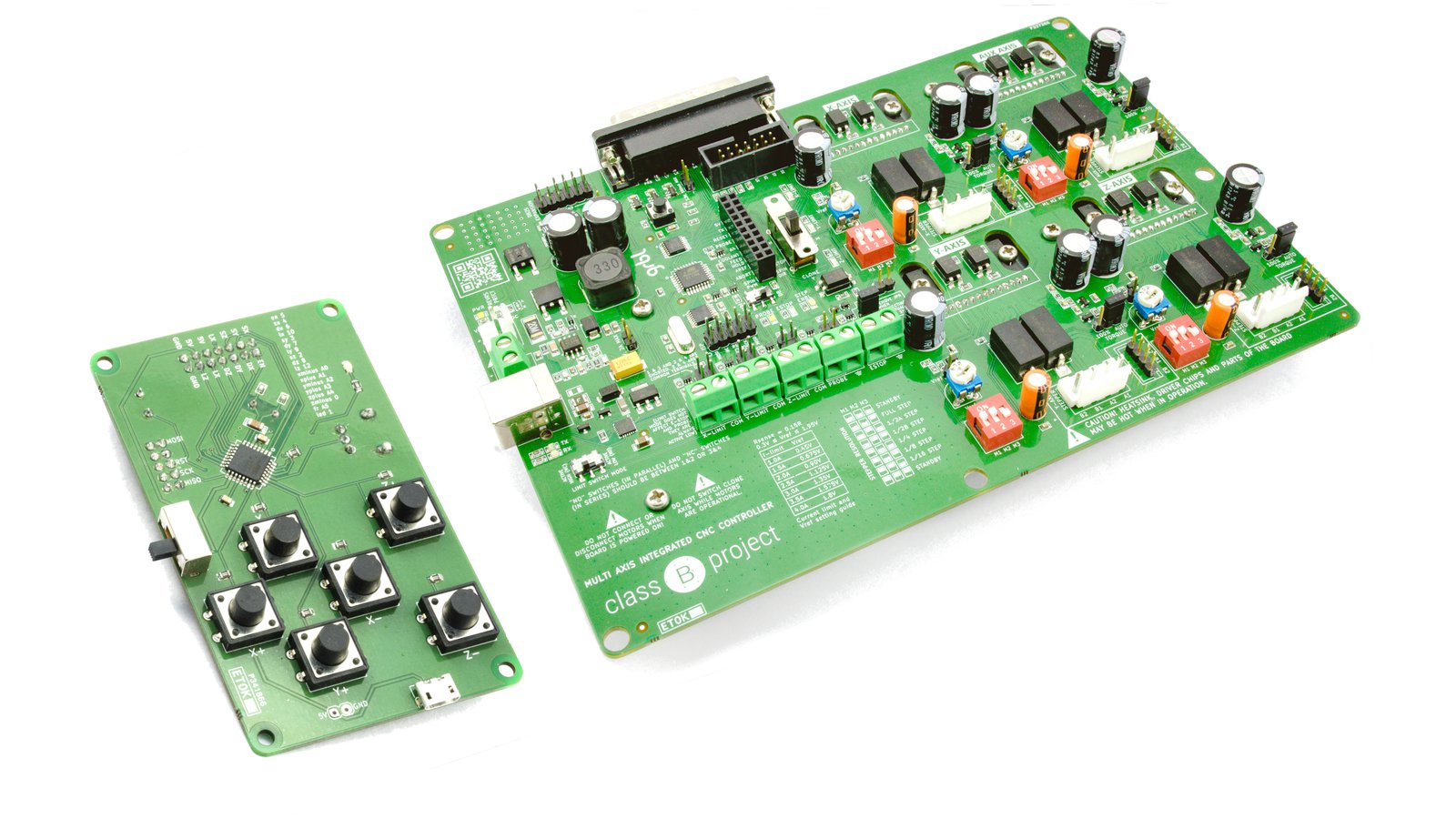

The motionPro 6600 is a four-axes motion controller for stepper motor-driven machines that comes with integrated, high-powered motor drivers. The hardware is designed to be software agnostic and will work with any logic that puts out TTL-level step and direction signals. This expands the scope of applications significantly, since you are not limited to a single, proprietary controller software and can write your own custom software drivers.

The motionPro 6600 is designed to be user-friendly and can be used by anyone, from those with little to no electronics knowledge, such as students, hobbyists, and budding makers, all the way to trained and experienced professionals with backgrounds in engineering and electronics such as professional developers, machinists, and product designers. The controller is designed in such a way that it can adapt to your growing skill levels and demands from increasingly sophisticated machine design.

The motionPro 6600 comes integrated with the latest version of grbl firmware, but it can also be controlled using external software such as the popular Mach 3, LinuxCNC, or even custom software written by you for bespoke applications. The controller eliminates the need for any external drivers and comes equipped with four high-powered, independently configurable, Toshiba stepper motor drivers.

The motionPro 6600 is vital for anyone who owns or builds:

This controller is also for folks who have one machine and are possibly looking to use the same machine for different purposes. For example, some might start with a laser engraver but at some point want to have a mill. With this controller, users can run both without having to modify any electronics.

DIY’ers and makers - These are folks like me who started with a simple project, got hooked, and learned plenty along the way. They have a fair idea of what they want in terms of electronics and are looking for solutions that scale with their needs. This group also include experienced builders, possibly with educational backgrounds in electronics and mechanical engineering, who have specific features in mind when selecting electronics for their machines such as, being software agnostic, scalable in terms of their future needs, etc. For example, a maker who owns a laser can easily upgrade to a mill and vice-versa without any changes to the electronics.

Industrial designers - These are folks who have learned a lot about design, are now working with a design firm, and possibly know a lot about manufacturing processes as well. These are people who work with digital fabrication tools very often and either have a personal mill in their homes/offices or are planning to get one. The motionPro 6600 is perfect for them. These users have a varied set of demands since they work with different materials and processes. This controller has the features that let them accommodate everything they want to do today and later in the future. For example, they can rapidly prototype using the onboard logic, while for small batch runs they can use more professional software.

Industrial users - These are folk who own businesses and typically have at least one precision motion machine in their shop. This board benefits these folk in terms of replacing faulty/improper cheap hardware that may have seemed adequate for experimentation, but cannot be relied on for long-term, rugged use. They also include folk who work in robotics and need for fine motion control. With a heavy-duty heatsink and rugged physical interfaces, this controller can stand on its own in any harsh industrial environment.

Makers of consumer products - These are folk who make consumer products that utilise stepper motors, such as camera sliders, consumer grade robots, etc. This controller is especially suitable for folk who are testing out new designs such as mechanical arms or a novel camera slider and who need the ability to load their custom firmware onto the controller.

Folk who run educational and vocational training institutions and maker spaces/labs - These are places where kids and students learn and experiment with mechatronics. These are also community spaces where folks can ‘rent’ machines to bring their projects to reality. This controller is useful for machines in these places because it can reduce costs by using a single machine for different purposes. For example, you can configure interchangeable attachments that work as a mill that can also be used as a laser engraver, all without swapping out the electronics. The laser engraver bundle can help you do exactly this.

Research lab personnel - These are people who need custom made plastics in their research. These include parts for custom prosthetics and other medical applications. While it would be easy to contract these to a fab, it’s more cost effective to have a mill in-house. Research labs have very diverse needs and designs and using a commercial fab for incremental changes can be very expensive. With this controller, researchers can mill parts or use the machine for other custom work without having change the electronics.

I have always been a tinkerer. Electronics was my passion and though I chose a career far away from engineering, I have always kept in touch and kept working on hobby projects. At one point I was creating a lot of PCBs with surface mount devices and it was getting very expensive to create stencils for all of them. I realised that I needed a low-power laser that could carve out stencils from common plastics. I eventually built a laser engraver/cutter which did cut stencils.

However, I was now hooked. The world of DIY was just too cool to let go after one project. I then built my own 3D printer and then upgraded my laser to a more rugged machine with the option of attaching a mill to it.

All along, I realised that a variety of software controls all of these machines and, unfortunately, the software typically support only a limited set of electronic hardware. I thought to myself it would be really handy to have hardware that works with a bunch of different software and physical interfaces, and is powerful enough to serve through a user’s increasing levels of sophistication as they grow and learn as a maker. It also had to be easy enough to use and be useful for a variety of experience levels from basic consumers and kids just experimenting all the way to experienced, professional makers.

My initial design was a success which the motionPro 6600 expands on considerably.

As I kept working on my projects and kept talking to others in this space, I realised the different needs they have. I kept integrating these needs into the controller.

All motionPro 6600 controllers come with a variable feedrate custom jogger. All connectors and crimp pins are also included in the package. No tools are included. Also a fan is not included and not needed under normal operation. However, if you are mounting the controller in a box, a standard 80 mm or 120 mm computer fan should be placed so that it directs air at the heatsink.

Visit this site for detailed documentation.

| | motionPro 6600 | Gecko G540 | CNC xPro V3 | Smoothieboard v1 | Buildbotics | Duet 3D | Smoothstepper |

|—————————————————————————————————- |————————————————————————————————————————— |———————- |——————- |————————— |——————- |—————————- |———————————- |

| Price | $250 | $269 | $120 | $190 | $450 | $170 | $180 |

| Integrated motor drivers | Yes | Yes | Yes | Yes | Yes | Yes | No ~danger |

| Max current per channel | 4 A ~success | 3.5 A | 2.2 A | 2 A | 6 A ~success | 2.4 A | NA |

| Max voltage | 40 V ~success | 50 V ~success | 24 V | 24 V | 36 V | 24 V | 5 V |

| Software agnostic | Yes ~success | No | No | No | NA | No | No |

| Number of Axes | 4 ~success | 4 ~success | 3 | 3 + 2 extruders | 4 ~success | 3 + 2 extruders | 6 ~success |

| Logic input physical interfaces | Parallel port, USB, IDC header ~success | Parallel port | USB | USB, Ethernet | Web/JSON | WiFi/Ethernet, USB | Ethernet, USB |

| Onboard logic | Yes | No ~danger | Yes | Yes | Yes | Yes | Yes |

| Electrical isolation between logic and drivers | Yes ~success | No | No | No | NA | No | Ethernet version only |

| Noise filtered endstops, probe and emergency stop | Yes ~success | Yes ~success | No | Yes ~success | Yes ~success | NA | NA |

| Over-current protection | Yes | Yes | Yes | Software only ~warning | Yes | Software only ~warning | No ~danger |

| Individually configurable axes on hardware | Yes ~success | NA | Yes ~success | No | Yes ~success | No | No |

| Reverse connect protection | Yes ~success | NA | No | Yes ~success | Yes ~success | NA | NA |

| Independently adjustable torque settings (apart from max current) | Yes. Can be set to 100% or AUTO which determines torque based on the step pulses ~success | No | No | No | No | No | No |

| Comprehensive heat management | Yes ~success | No | No | No | Yes ~success | No | No |

| Optimally supported stepper motors | NEMA 17 NEMA 23 NEMA 34 NEMA 42 | NEMA 17 NEMA 23 NEMA 34 NEMA 42 | NEMA 17 NEMA 23 | NEMA 17 | NEMA 17 NEMA 23 NEMA 34 NEMA 42 | NEMA 17 | NA |

NA indicates that the information is either not available or not validated.

"Designed for any application or project that uses stepper motors for fine motion control, the motionPro 6600 has been created for makers, developers and enthusiasts..."

"Access is via plain old TTL or USB with opto-isolators and noise filters for added protection."

Produced by Class B Project in Pune, MH, India.

Sold and shipped by Crowd Supply.

Includes the motionPro 6600 Controller and a custom-made jogger. All pledge levels include compatible connector housings and pins.

I'm a software services marketer while my wife is a test data manager. I've been tinkering with electronics with my dad since I was 5 years old. That led to me being an electronics engineer. However my career path took a detour with electronics becoming a serious hobby and now a passion.