plugg.ee Labs

Robotics & Motors

KiCad

plugg.ee Labs

Robotics & Motors

KiCad

JuicyBoard is the foundation of a modular, open source platform that makes it easy for you to build a custom 3D printer, CNC router, or any other device driven by stepper motors. The idea is simple, unlike other control boards, JuicyBoard is not pre-populated with any drivers, switches, or other functions. Instead, it includes only the components for common, core functions (e.g., microcontroller, USB port, SD card, etc.), so you have control over adding just the necessary functional modules for your application. This modular approach gives the platform a number of advantages over static board designs, as we explain below.

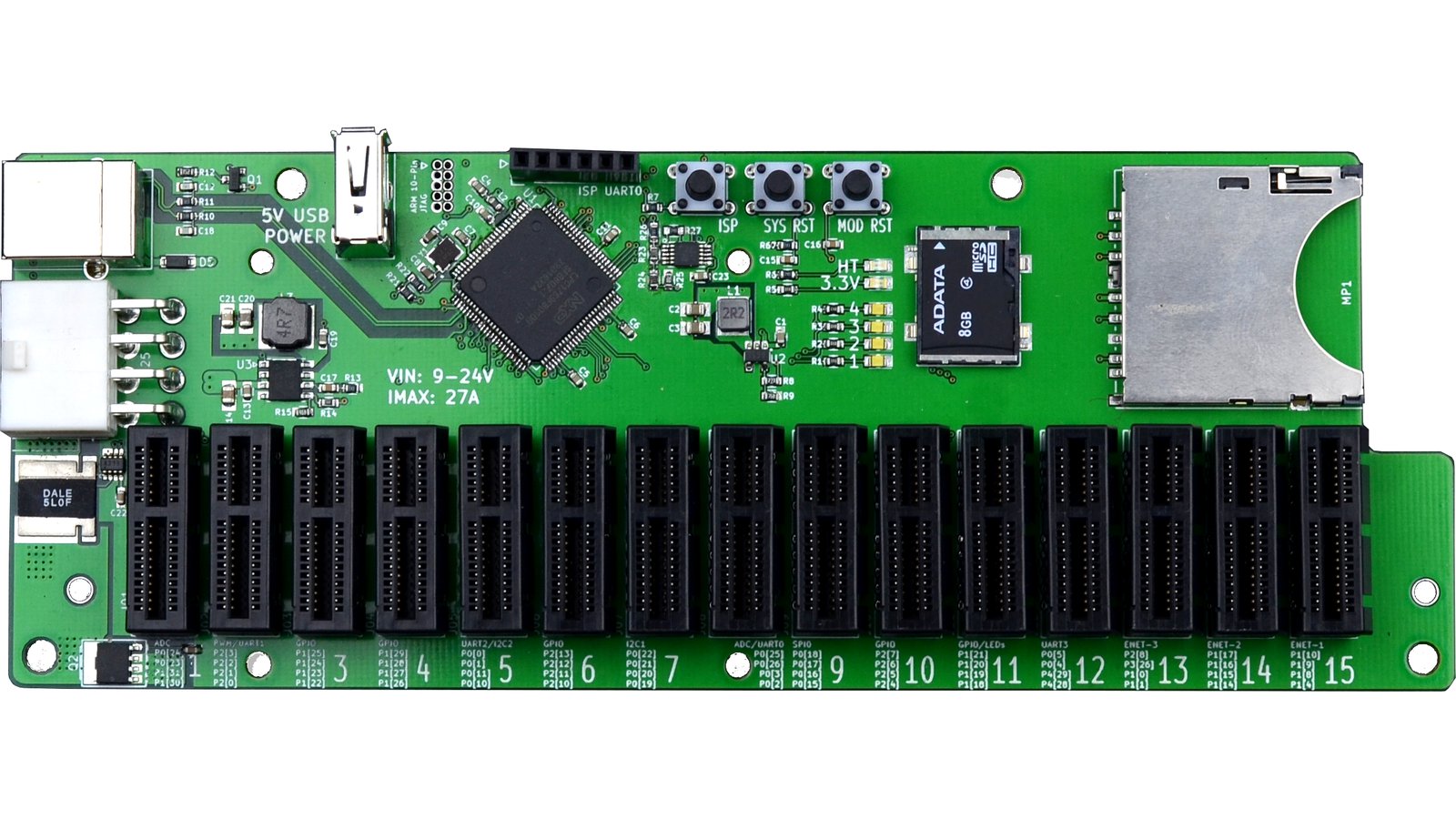

JuicyBoard R1000AX base board has the following features:

In addition to the modules available below, we’d like to hear your feedback and suggestions for new modules. This is our current wish list:

We’re very open to working with other people who have cool modules that can work nicely with JuicyBoard, lately we spoke with ODrive team, a very interesting brushless motor driver with postion control that can interface with JuicyBoard through CAN. We’re planning to write Juicyware drivers that allows using brushless DC servos in your application! Check out this cool video of ODrive actuating XY axes of a router.

So far, we’ve used JuicyBoard to build a couple of 3D printers and a CNC machine. Here’s a case where we used it to build a system for controlling a triple extruder, triple-head 3D printer (using polystroooder) that can print three different materials. Here is how we configured a 10-slot prototype JuicyBoard to drive this printer:

R1008 is still new, we’re planning to upgrade the machine with PT100 sensors instead of thermistors. It will take some extra machining as well.

Check out our video above for more applications. We’ll be releasing updates illustrating other applications as well, so make sure you’re signed up.

The idea first came up after we attempted to build a custom 3D printer. At first, we tried several off-the-shelf boards, but these caused several points of frustration:

To solve these problems, we came up with a completely different architecture and approach

We created a platform that has a base board (JuicyBoard) that includes all the essential basic functions of every system (the main processor, power supplies, communication port and flash storage). Then we arranged a set of sockets that allow users to plug in modules that perform only the features they need in a given application.

We designed the system to be as flexible as possible. For example, a stepper motor driver can be plugged into any slot. However, some special function modules (like the R1005 Analog Inputs) must be plugged into specific slots that connect to the CPU’s analog pins.

We added a full suite of telemetry functions (measuring voltage, current, and temperature) to the base board and to some modules. That lets users monitor the health of the system in real time, so they can detect and isolate failures. It’s easy to replace the faulty modules without reworking the system.

We also added in a hot swap controller, which acts like an electronic fuse that detects abnormal power supply conditions (like over-voltage, under-voltage or current overloading) and shuts down the system. The controller has an input for attaching a mechanical kill switch, which is the most reliable way to shut down the system in case of emergencies.

Another benefit we figured out afer working with JuicyBoard for awhile is the ability to upgrade the system with minimum reworking of hardware and firmware. For example, say we build a 3D printer with NEMA 17 motors and we later want to make a mega-size of the same 3D printer (say with NEMA 34 steppers). With JuicyBoard, we only need to design a larger motor driver module that accepts the same input control as R1001, then we can upgrade the system with the new motors with minimal revisions to firmware. Similarly, users could upgrade their system with a later revision of JuicyBoard that has an updated CPU or power capabilities, while keeping their add-on modules largely unchanged.

We love open source. A fundamental tenet of our philosophy is a belief in the power of the community to drive improvements of any designs or products out there. We’re exclusively using open source PCB design tools to create our boards. And, we’ve decided to open source all JuicyBoard and module hardware and firmware under GPL v3.0, so others can further evolve the platform and possibly enrich it with modules we’ve never thought of before. To that end, we have created a template KiCAD PCB project that’s an easy starting point for anyone who wants to design and build their own module.

JuicyBoard runs Juicyware, which is a fork of Smoothieware and is open sourced under GPL v3.0. Similar to our hardware architecture, Smoothieware is modularly structured firmware that allows adding and modifying functions easily and efficiently. It’s based on ARM’s mbed library, which means it has a path to portability to other microcontrollers in the future. Juicyware can be found in GitHub.

The short answer is no, here’s why

When we were planning how to connect modules to the board these were the factors that we considered:

We looked at different connectors and we reached the conclusion that PCIe is pretty much the most used connector on the planet. There are lots of manufacturers and reliability much better than it used to be. All other M+F connecting pairs we’ve seen were either large (the system will be much bigger for the same configuration) or expensive, and some were mechanically fragile.

There’s also another advantage for using PCIe connectors, the mating of the PCB and the connector provide enough vertical mechanical support without the need for adding extra support structures per module. To make the whole system rigid we designed a bracket the secures all modules in place and prevents them from wiggling horizontally.

There are a couple of drawbacks using PCB edge connector

There are a couple of ways to implement closed loop stepper motor control

Lastly, you can use ODrive as a closed loop brushless DC motor controller, it interfaces through CAN and can be accessed using an R1003 module.

"The Plugg.ee Labs Cortex-M3 based “JuicyBoard” robotics kit is designed for building stepper motor controlled devices like 3D printers or CNC routers."

Produced by plugg.ee Labs in San Jose, California.

Sold and shipped by Crowd Supply.

This is the JuicyBoard with all bells and whistles! 15 feature slots + SD card slots + all the reliability and safety features.

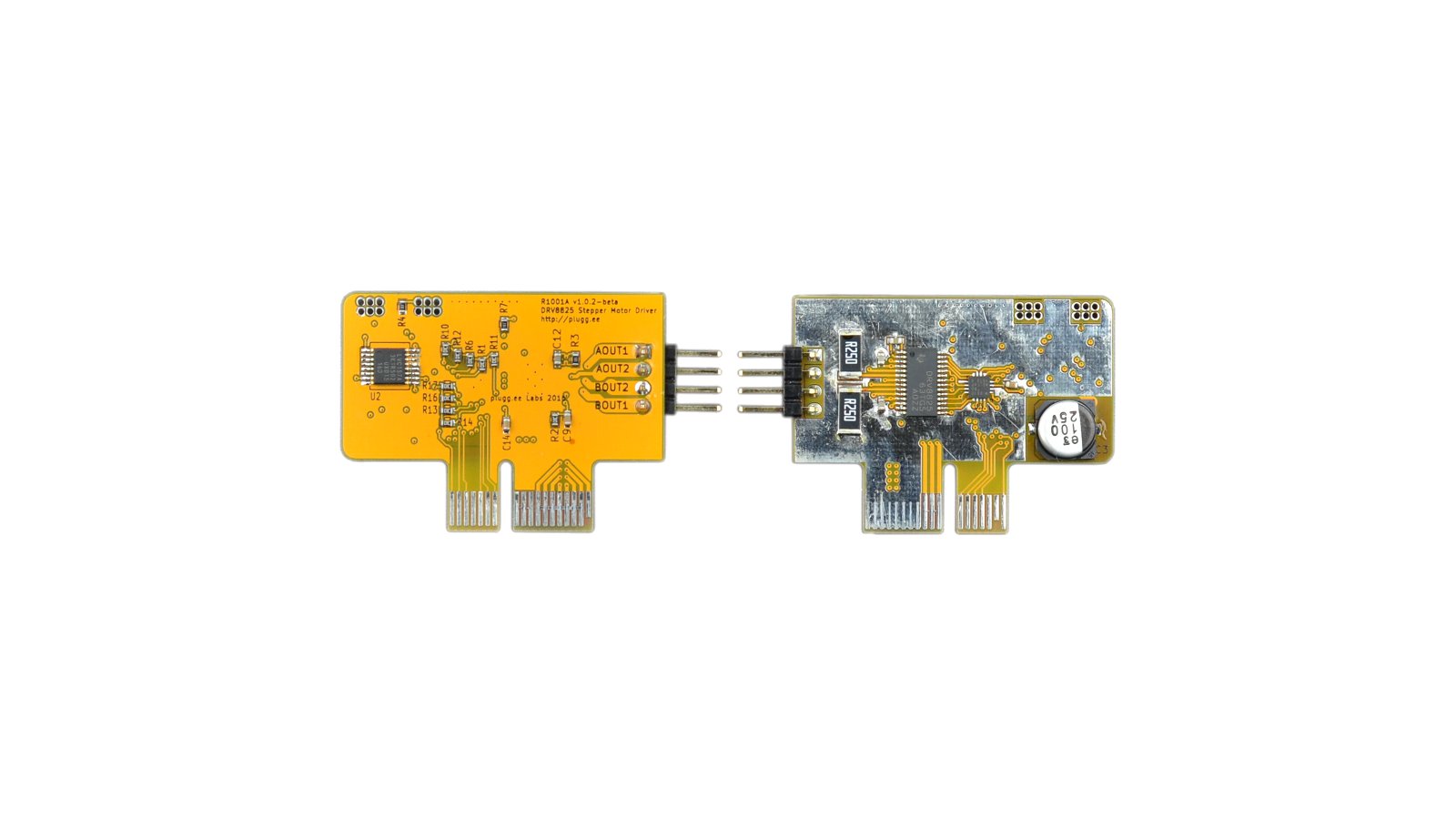

This is a NEMA stepper motor driver based on TI's DRV8825 chip. It's a high-performance stepper driver capable of micro-stepping at 1/32” resolution. Current can be digitally set for every driver in 10 mA increments. The R1001 includes temperature/voltage/current monitors for real-time performance measurement and fault detection.

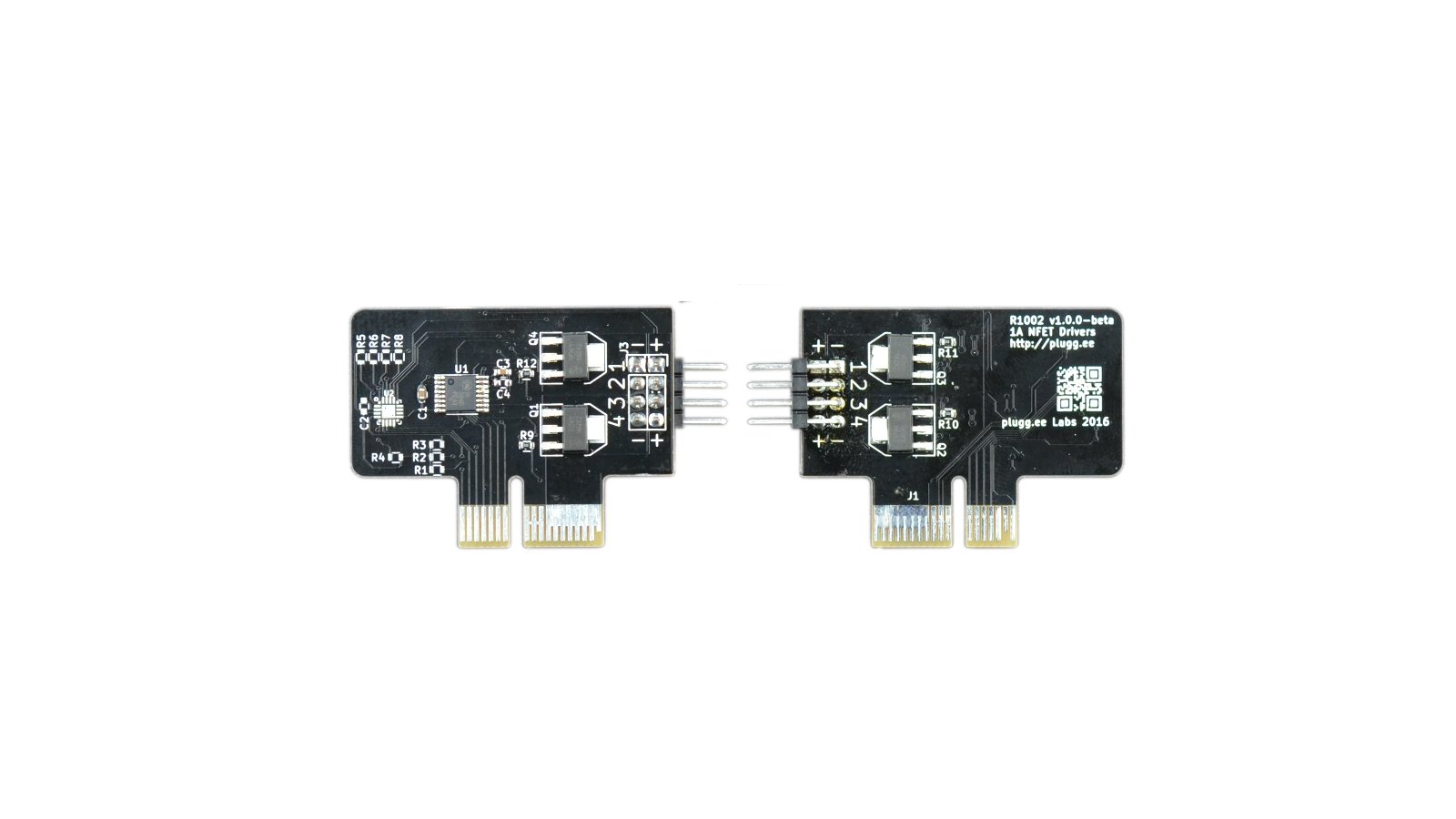

This module can control low-power peripherals, such as large LED status displays and fans. Maximum current limit of 1 A per channel, run at the high input voltage.

This module provides a quad channel analog or digital interface to the main CPU. It includes a 1% 4.7 kΩ resistor as required in most thermistor setups. Can be used for analog inputs, digital inputs, or outputs.

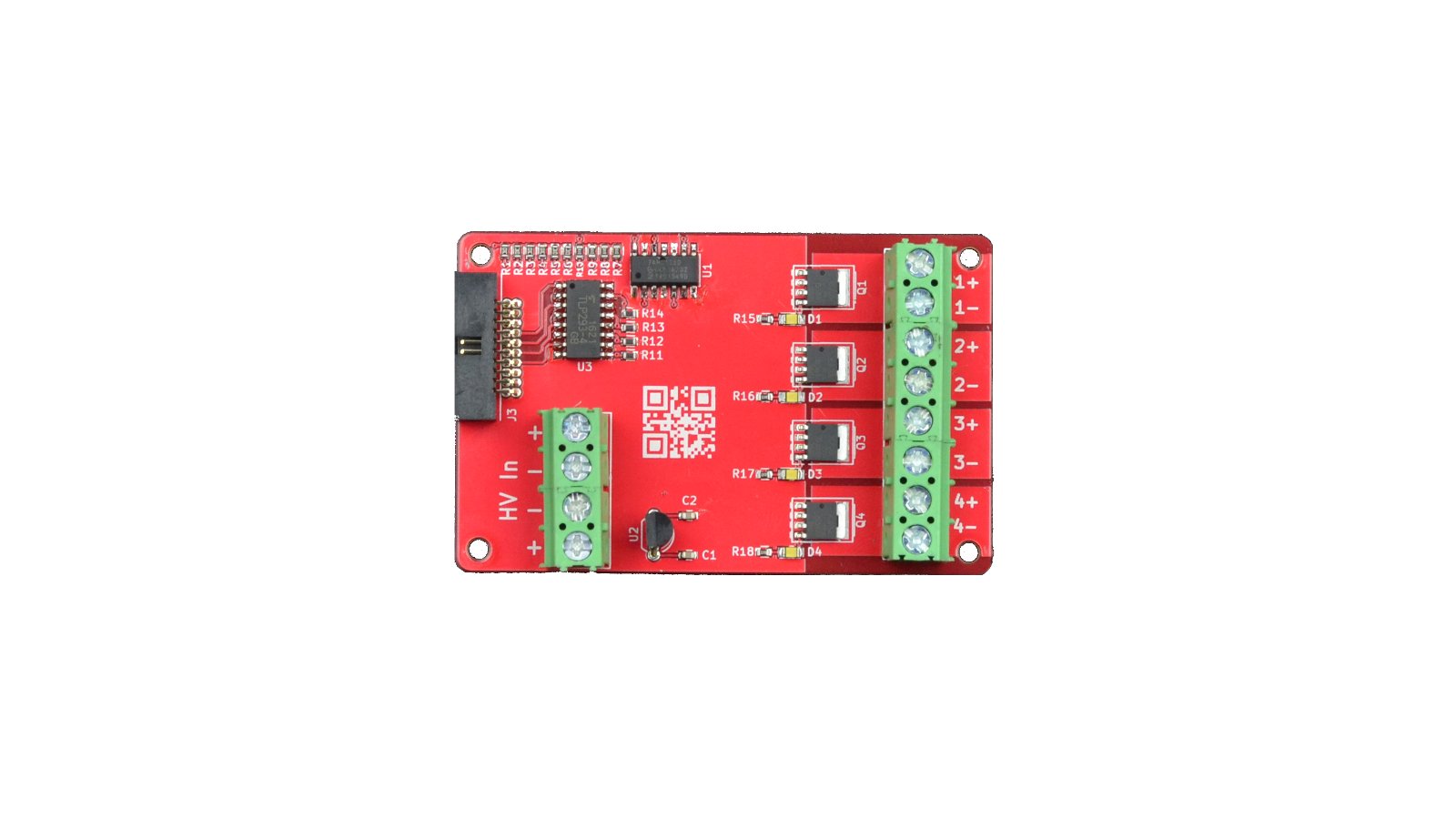

Super-low resistance PSMN1R2-30YLC,115 NFETs from NXP that can be used to drive four very large peripherals, like a large heater or a DC spindle. Want to run a 300+ W heat bed? No problem. The transistors are rated 100 A, with less than 2 mΩ series resistance. The R1007 must be powered through its own auxiliary supply input (up to 24 V) and is optically isolated from JuicyBoard, which means it can have its own separate power and ground. Includes the necessary R1005 extender module.

San Jose, California · plugg.ee

I love to design and make cool gadgets, I previously made the WiFi controlled smart plug.